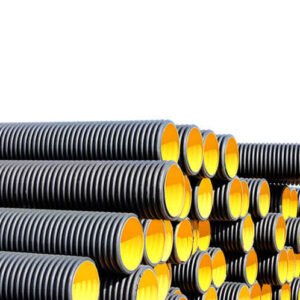

1. HDPE injection molded pipe fittings

HDPE injection molded pipe fittings are a kind of pipe connection device that uses an injection molding machine to heat and melt thermoplastic plastic and then inject it into a steel mold to form. It has the following characteristics:

1. Reliable quality: HDPE injection molded products have the advantages of high precision, high strength, high corrosion resistance and low temperature performance, so they are not prone to breakage, wear and other problems during use.

2. Good sealing: The structural design of HDPE injection molded pipe fittings has good sealing performance, which can effectively avoid fluid leakage in the pipeline and ensure the smooth progress of the production process.

3. Economical and practical: HDPE injection molded pipe fittings have low cost, high production efficiency, excellent economy and practicality, and are widely used in industry, construction and other fields.

Socket-and-socket connection

Butt 45-degree elbow

Butt 90-degree elbow

Butt flange head

Butt cross

Butt-joint different straight-through

Butt tee

Welding 45-degree elbow

Welding 90-degree elbow

Welded oblique tee

Welded tee

Welded right cross

2. Classification of injection molded pipe fittings

Injection molded pipe fittings can be divided into the following categories according to different applications and shapes:

1. Elbow: Usually used to connect equipment and pipes at turns in pipelines, with different angles such as 45 degrees and 90 degrees.

2. Pipe joints: usually include direct connection type, reducing type, same diameter type, tail port type, winding type, etc., used to connect pipes of different shapes and sizes.

3. Tapered tube: used to connect pipes of different diameters, widely used in throttling, mixed fluids and other fields.

4. Flange: A round or square interface that connects the pipe wall to equipment such as valves and pumps.

3. Main applications of injection molded pipe fittings

Injection molded pipe fittings have a wide range of applications. They can not only be used to transport ordinary liquids, gases and solids, but can also be used in medical, food, chemical, electric power, pharmaceutical and other industries. The following are the main applications of injection molded pipe fittings:

1. Industrial transmission pipeline: suitable for transporting various industrial fluid media, such as acid, alkali, salt, water, oil, etc.

2. Building pipelines: suitable for drainage pipes, hot water pipes, water supply pipes, etc. in buildings.

3. Medical pipeline: suitable for hospital infusion pipelines, hemodialysis pipelines, etc.

4. Environmentally friendly pipelines: suitable for transporting waste water, waste gas, etc., and have wide applications in the field of environmental protection.

Reviews

There are no reviews yet.