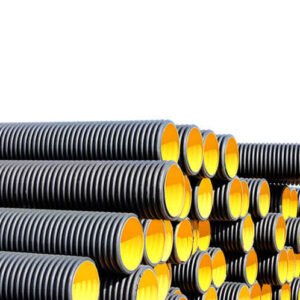

Anti-corrosion and thermal insulation pipes

Insulated pipe is the abbreviation of insulated pipe. Insulated pipe is used for the transportation of liquid , gas and other media, and is used for thermal insulation of pipelines in petroleum, chemical industry, aerospace, hot spring , military, central heating, central air conditioning, municipal and other industries. Insulated pipe is suitable for conveying various media within the range of -50℃-150℃ . It is widely used in the transportation of central heating, cooling and hot oil, as well as thermal insulation and cold preservation projects in warm rooms, cold storage, coal mines, petroleum, chemical and other industries.

High-temperature prefabricated direct-buried insulation pipe mainly consists of four parts.

( 1 ) Working steel pipe: According to the technical requirements of the transmission medium, seamed steel pipes, seamless steel pipes, and double-sided submerged arc spiral welded steel pipes are used .

( 2 ) Insulation layer: Made of rigid polyurethane foam.

( 3 ) Protective shell: made of high-density polyethylene or fiberglass.

( 4 ) Leakage alarm line: When manufacturing high-temperature prefabricated direct-buried insulation pipes , an alarm line is buried in the insulation layer close to the steel pipe. Once leakage occurs somewhere in the pipeline, through the conduction of the alarm line, a special detection instrument can be detected It will alarm and display the exact location of the leak and the extent of the leak, so that maintenance personnel can be notified to deal with the leaking pipe section quickly to ensure the safe operation of the heating network.

Insulation pipe features

High temperature prefabricated direct buried thermal insulation pipe – advantages and features

- It has strong corrosion resistance and waterproof ability and low overall cost.

According to calculations by relevant departments, double-pipe heating pipes can generally reduce the project cost by about 25% (using fiberglass as the protective layer) and 10% (using high-density polyethylene as the protective layer).

- Low heat loss, saving energy. The heat loss is only25%of traditional pipes.

Direct buried insulation pipe thermal conductivity 0.022kcal/mh℃ water repellency 0.03kg/cm³

- Long service life

Correct installation and use can extend the life of the pipe network to 30-50 years with extremely low maintenance costs.

- Less space and faster construction are beneficial to environmental protection.

It can reduce the amount of earth excavation by more than 50% and the amount of earthwork masonry and concrete by 90%.

It is much lower than other commonly used insulation pipe materials in the past, and the insulation effect is improved by 4 to 9 times. In addition, its water absorption rate is very low, about 0.2kg /m2 . The reason for the low water absorption rate is that the closed-cell rate of polyurethane foam is as high as about 92% . The low thermal conductivity and low water absorption rate, plus the insulation layer and the high-density polyethylene or fiberglass protective shell with good waterproof performance on the outside, have changed the traditional trench laying heating pipeline ” wearing a wet cotton jacket ” situation, greatly reducing the overall heat loss of the heating pipeline, and the heat loss of the heating network is 2% , which is less than the international standard requirement of 10% .

Anti-corrosion, good insulation performance and long service life.

The polyurethane rigid foam insulation layer of the insulated pipe is tightly bonded to the outer skin of the steel pipe, which isolates the infiltration of air and water and can play a good anti-corrosion role. At the same time, its foaming holes are closed and its water absorption is very small. High-density polyethylene shell and fiberglass shell have good anti-corrosion, insulation and mechanical properties. Therefore, the outer skin of the working steel pipe is difficult to be eroded by outside air and water. As long as the water quality inside the pipeline is well treated, according to foreign data, the service life of high-temperature prefabricated directly buried insulated pipes can reach more than 50 years, which is 3 to 4 times longer than traditional trench laying and overhead laying .

4 . It occupies less space, is quick to construct, and is conducive to environmental protection.

Directly buried heating pipes do not require the construction of huge trenches, but only need to bury the insulated pipes underground, thus greatly reducing the project area, reducing the amount of earth excavation by about 50% , and reducing the amount of civil masonry and concrete by 90% . At the same time, the processing of insulated pipes and on-site trenching are carried out in parallel, and only on-site joints are needed, which can shorten the construction period by more than 50% .

【product description】

1. Applicable to pipe network systems with medium temperature not higher than 120℃ , occasional peak temperature not higher than 140℃ , and working pressure not higher than 2.5Mpa . Polyurethane insulation pipe can work continuously for at least 30 years in 120℃ environment .

2. The products are widely used in anti-corrosion, thermal insulation and heat preservation pipeline projects in the fields of heating, cooling and crude oil transportation.

Reviews

There are no reviews yet.