Reinforced Thermoplastic Pipe

- Introduction

Reinforced Thermoplastic Pipes use polyolefin wear-resistant material as the wear-resistant layer and are compounded with the base pipe through co-extrusion. The long-term operating temperature is below 45 °C and are suitable for transporting various liquids, slurries, etc. that have wear-resistant requirements. Reinforced thermoplastic pipes in granular solids.

- Name/terminology

2.1 Polyolefin wear-resistant material:

A material mainly made of polyolefin that has both wear resistance and processability.

2.2 Wear-resistant layer:

The inner layer of the pipe is made of polyolefin wear-resistant material with a certain thickness and wear resistance.

2.3 Base tube:

The pipe body of the polyolefin composite wear-resistant pipe is obtained by removing the wear-resistant layer.

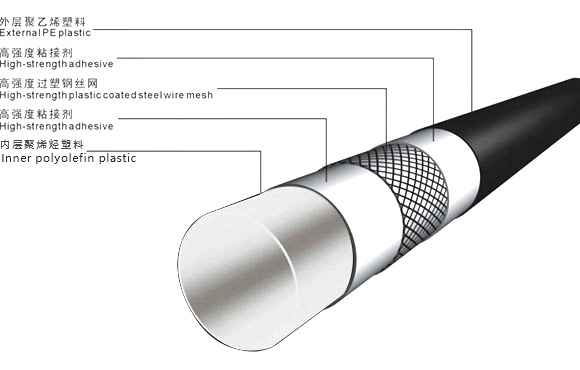

2.4 Reinforced Thermoplastic Pipe(RTP):

The pipe is made of wire mesh skeleton Reinforced Thermoplastic Pipe as the base pipe and co-extruded with polyolefin wear-resistant material.

- Structural diagram of Reinforced Thermoplastic Pipe

- Technical indicators

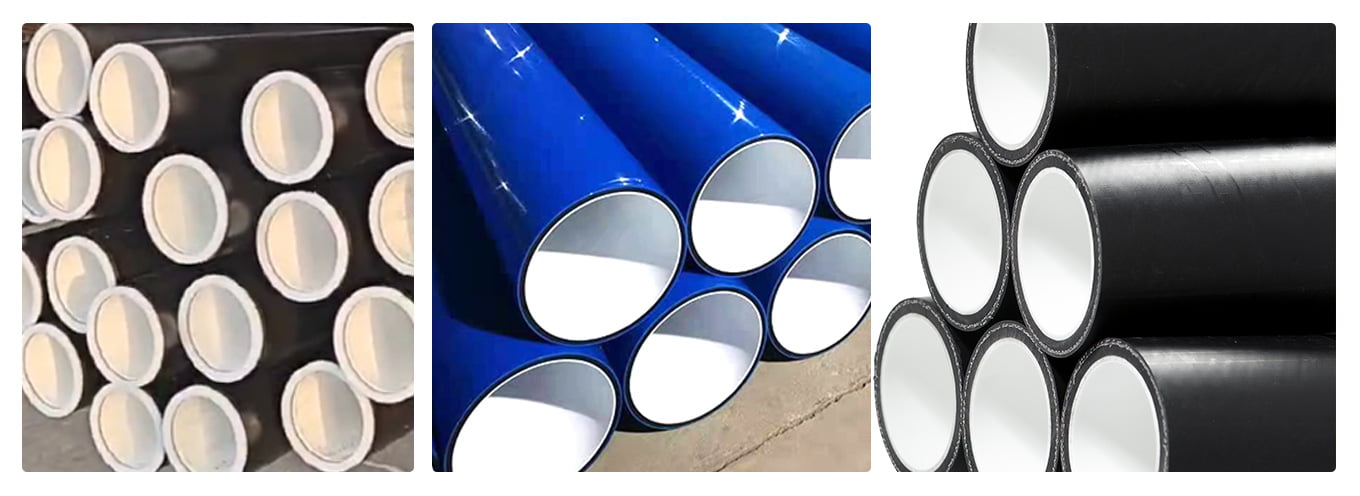

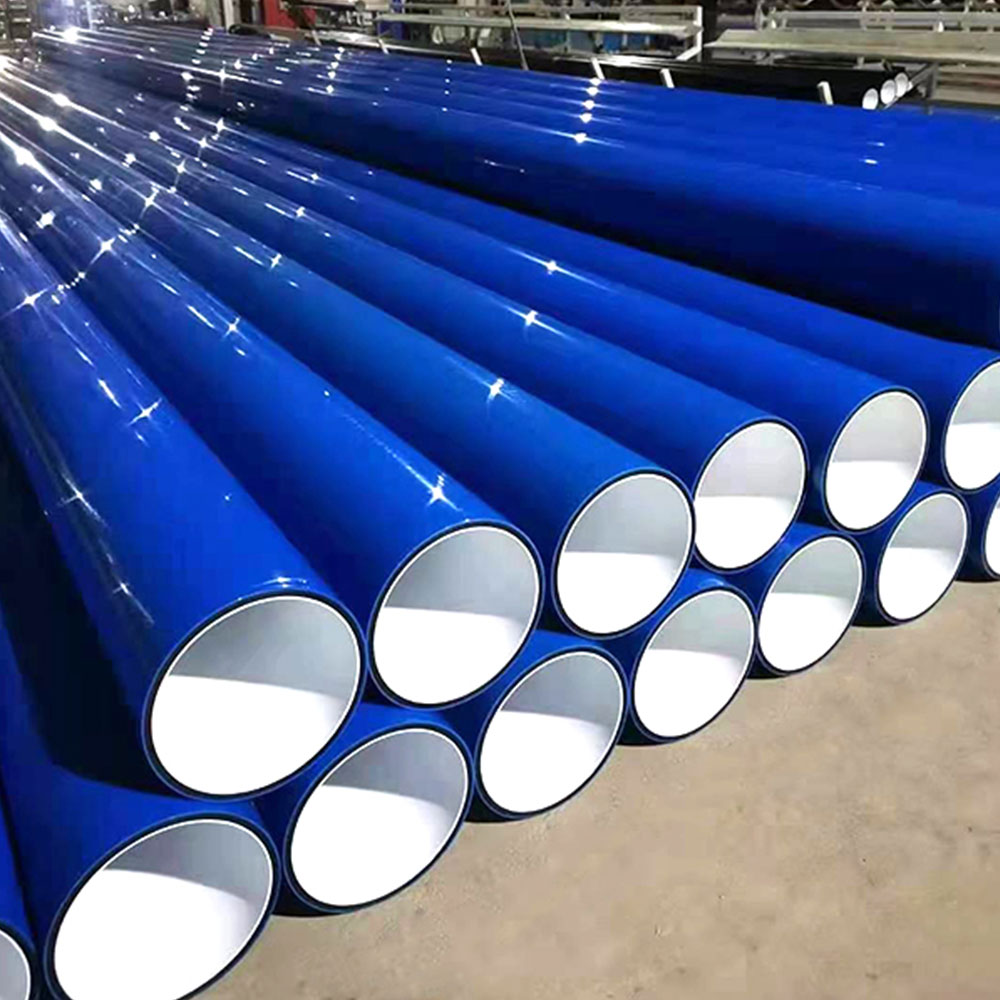

4.1 Color

The color of the wear-resistant layer should be clearly different from the color of the base tube. The wear-resistant layer is generally white, and the base tube is generally black, which can be customized according to requirements.

4.2 Dimensions and deviations of base pipe

The base pipe dimensions and deviations of Reinforced Thermoplastic Pipes comply with the regulations of GB/T 13663.2 .

4.3 Base pipe length

Pipe lengths are generally 6m , 9m , and 12m, and can also be agreed upon by both parties.

Features

- High wear resistance: The wear resistance is3-4times that of ordinary polyethylene molecular weight polyethylene pipes ;

2 . High corrosion resistance: acid resistance, alkali resistance, chemical corrosion resistance, electrochemical corrosion resistance;

- Wide pressure range: pipes with different structures can be applied to0.6-9.0MPa working conditions;

4 . Good toughness and high composite strength : three-layer co-extrusion, elongation at break >1000% ;

- Easy installation: hot melt connection, electric fusion connection and mechanical connection can all be used, and the installation is quick;

- Good economy: long service life, low construction, maintenance and operation costs.

- Hydraulic characteristics: The equivalent roughness of the inner wall of the pipe is between0.0015-0.015ram , while the equivalent roughness of the steel pipe is generally 0.19nHn ( generally after three years, the hydraulic characteristics of the steel pipe deteriorate due to corrosion and scaling. The equivalent roughness of the inner wall is calculated as 0.6mm. Therefore, the inner wall of the pipe is smooth and not easy to scale, with small transmission resistance and good energy-saving effect. The transmission capacity can be increased by 20-30% compared with traditional pipelines such as steel pipes.

Wear-resistant layer performance indicators

| serial number | project | index | Detection method |

| 1 | Density, g/ cm³ | 0.90 ± 0.02 | GB/T 1033.1-2008 |

| 2 | Melt mass flow rate ( 190 ℃ /2.16kg ), g/10min | 0.50 ± 0.20 | GB/T 3682.1-2018 |

| 3 | Tensile strength, MPa | ≥ 20 | GB/T 1040.3-2006

( Type 5 dumbbell specimen) |

| 4 | Tensile strain at break, % | ≥ 600 | |

| 5 | Low temperature impact embrittlement temperature, ℃ | ≤ -40 | GB/T 5470-2008 ( Method A ) |

| 6 | Oxidation induction time (200 ℃ ) , min | ≥ 30 | GB/T 19466.6-2009 |

| 7 | Mortar wear rate, % | ≤ 0.30 |

Application scope of Reinforced Thermoplastic Pipes:

Chemical industry : pipelines for conveying solid-liquid mixtures such as coal powder, silicon powder, salt slurry, alkali slurry, etc.;

Electric power: such as process pipelines for ash removal, slag removal, powder feeding, powder return, and desulfurization in thermal power stations;

Metallurgy: such as long-distance pipeline transportation of concentrate slurry and tailings, and mineral and solvent process pipelines in ore dressing plants;

Cement: such as raw slurry transportation of rotary kiln wet production line, coal powder transportation, elevator unloading, finished cement pneumatic transportation loading and unloading, concrete transportation pipeline;

Pipe connection methods: crimping flange connection, double sealing flange connection, electric fusion flange connection, flanging integrated flange connection

Reviews

There are no reviews yet.