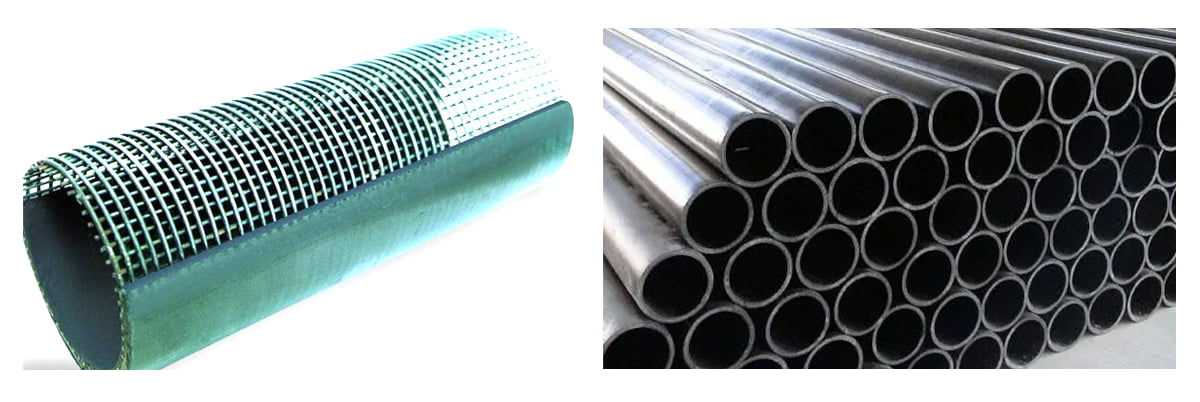

Steel skeleton composite pipe

Description of application fields of steel frame plastic composite pipes

Since the structure of the steel frame plastic composite pipe is similar to reinforced concrete, it can not only have a high pressure bearing capacity like a metal pipe, but also can withstand the erosion of various biological and chemical substances like a plastic pipe. It overcomes the resistance of steel pipes. They are not resistant to corrosion. Pure plastic pipes are not resistant to corrosion and pressure. Glass fiber reinforced plastic pipes have strict requirements for construction conditions. Plastic-lined pipes and similar composite pipes such as steel plate mesh pipes and steel wire wound pipes are prone to delamination, have low temperature resistance, and lack connection reliability. It has shortcomings such as the lack of matching pipe fittings and has a good performance-price ratio. It is a substitute for traditional medium and low-pressure pipelines. Products are widely used in petrochemical, metallurgical and mining, electric power, airports and ports, municipal gas, water supply and drainage and other industries.

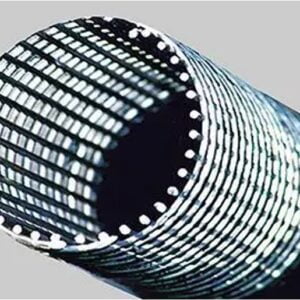

The performance of the product depends on the materials and structure it uses. The superior performance of the steel skeleton polyethylene plastic composite pipe depends on the rationality and advancement of its design, in addition to the use of the world’s best materials. It is a new type of double-sided anti-corrosion, pressure-resistant green pipeline product. The pipeline uses high-quality low-carbon steel wire mesh as a reinforcement frame and pipeline-grade high-density polyethylene ( HDPE ) as a matrix. It has the strength of ordinary steel pipes and can withstand the erosion of various biological and chemical substances like plastic pipes. It represents the development direction of the world’s pipelines.

- Good corrosion resistance

Compared with metal pipes, steel skeleton polyethylene plastic composite pipes, like PE pipes, have excellent resistance to chemical corrosion and have good corrosion resistance to more than 270 corrosive media such as acids, alkalis, salt solutions, organic solvents, etc.

- Good anti-wear performance

The wear resistance of steel frame polyethylene plastic composite pipes is 3 times that of steel pipes, see the table below; compared with plastic pipes connected by hot plate butt welding, steel frame polyethylene plastic composite pipes use electrofusion connection, so the connection transition is smooth , avoiding the boss formed at the inner wall connection of the hot plate butt welded pipe , effectively improving the wear resistance of the pipe.

- Smooth inner wall and small conveying resistance

The steel frame polyethylene plastic composite pipe adopts an internal shaping process. Its inner surface is smoother than the inner wall of the plastic pipe. The equivalent roughness is 0.01mm , while the equivalent roughness of the inner surface of the steel pipe is 0.2mm . The transportation capacity under the same conditions is higher than that of the steel pipe. Significant improvement.

- Good toughness

Steel skeleton polyethylene plastic composite pipe has a moderate elastic modulus, which is 4 times that of polyethylene pipe and one-sixtieth of that of steel pipe, indicating that the product has moderate toughness and inherits the characteristics of polyethylene flexible pipe, which is convenient for trenchless construction and slope laying, reducing construction costs.

This new type of pipeline is made of high-strength plastic steel skeleton and thermoplastic polyethylene as raw materials. The steel skeleton is used as the skeleton reinforcement of the polyethylene plastic pipe. It uses high-density polyethylene (HDPE) as the matrix. High-performance HDPE modified adhesive resin is used to tightly connect the steel skeleton with the inner and outer layers of high-density polyethylene, so that it has an excellent composite effect. Because the high-strength steel wire reinforcement is coated in continuous thermoplastic plastic, this composite pipe overcomes the shortcomings of steel pipes and plastic pipes, while maintaining the advantages of steel pipes and plastic pipes. The steel mesh skeleton plastic composite pipe adopts high-quality materials and advanced production technology to have higher pressure resistance. At the same time, the composite pipe has excellent flexibility and is suitable for long-distance buried water supply and gas pipeline systems. The pipe fittings used in the steel mesh skeleton polyethylene composite pipe are polyethylene electric fusion pipe fittings. When connecting, the heating element inside the pipe fitting is used to melt the outer plastic layer of the pipe and the inner plastic layer of the pipe fitting, so that the pipe and the pipe fitting are reliably connected together.

Reviews

There are no reviews yet.