Hdpe mining pipe introduction

Mining pipes are extruded using polyethylene resin as the main raw material and adding appropriate amounts of additives. In addition to its outstanding antistatic and flame retardant properties, this kind of pipe also has the advantages of high strength, good processing performance, strong environmental adaptability, excellent stress cracking resistance, and good creep resistance.

The raw materials for the production of PE mining pipes are special materials made of PE resin with high-efficiency antistatic agents and high-quality flame retardants.

1. Flame retardant and antistatic: The antistatic and flame retardant components of polyethylene pipes for coal mines are evenly distributed in the pipe body, so the antistatic and flame retardant performance indicators will not be affected by long use time. The antistatic and flame retardant properties comply with national standards and are suitable for specific underground flammable and explosive places.

2. Light weight and easy installation: Polyethylene pipes for coal mines have low density, and their unit weight is only 1/8 of steel pipes and 1/3 of fiberglass pipes. Therefore, polyethylene pipes for coal mines are not only easy to transport and install, but can also be used underground. Greatly reduce workers’ labor intensity and improve work efficiency.

3. Corrosion resistance and non-scaling: Polyethylene for coal mines has strong corrosion resistance and non-scaling properties, and is particularly suitable for underground transportation of high-sulfur water and water containing calcium, magnesium and plasma. It greatly saves the cost of anti-corrosion and descaling. The service life is much longer than that of steel pipes, and the comprehensive economic benefits are high.

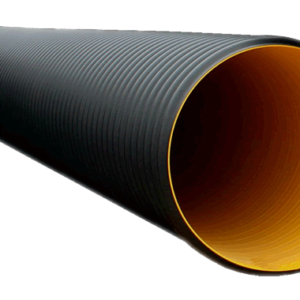

4. Self-lubrication: The inner wall of polyethylene pipe for coal mines is smooth, the resistance when transporting fluid is small, and the roughness is much smaller than that of steel pipes and fiberglass pipes. Under the same conditions, the transportation capacity can be increased by 30%. Good flexibility and strong resistance to geological settlement;

5. Good anti-aging and anti-rapid cracking properties: Polyethylene pipes for coal mines have good anti-aging properties, are not easily brittle at low temperatures, and have good anti-rapid cracking properties; they have good toughness and can effectively absorb impact energy; they have moderate bending modulus and are resistant to fracture The elongation rate is as high as over 400%. Under special operating conditions in coal mines where geological subsidence and other phenomena occur from time to time, polyethylene pipes for coal mines can effectively avoid fracture accidents compared with traditional rigid steel pipes and fiberglass pipes.

6. Good wear resistance: Comparative wear resistance tests between polyethylene pipes for coal mines and steel pipes show that the wear resistance of polyethylene pipes for coal mines is 4 times that of steel pipes. In the field of coal transportation, compared with steel pipes, polyethylene pipes for coal mines have better wear resistance, which means that polyethylene pipes for coal mines have a longer service life and better economy.

7. Impact resistance: Polyethylene has an extremely low low-temperature embrittlement temperature and can be used at lower temperatures.

8. High toughness: elongation at break generally exceeds 500%.

9. Good flexibility: The pipe can be bent and used for offshore dredging pipes to reduce soft rubber knots.

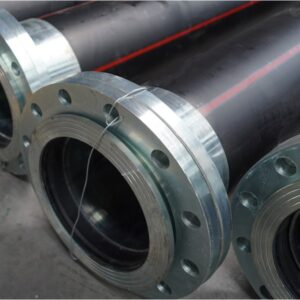

10. Easy connection: hot melt connection, pipe clamp connection or flange connection is used for easy construction.

What is the application scope of PE mining pipe?

Mine air ducts; mine water pipes; mine shotcrete pipes; mine gas pipes.

Reviews

There are no reviews yet.