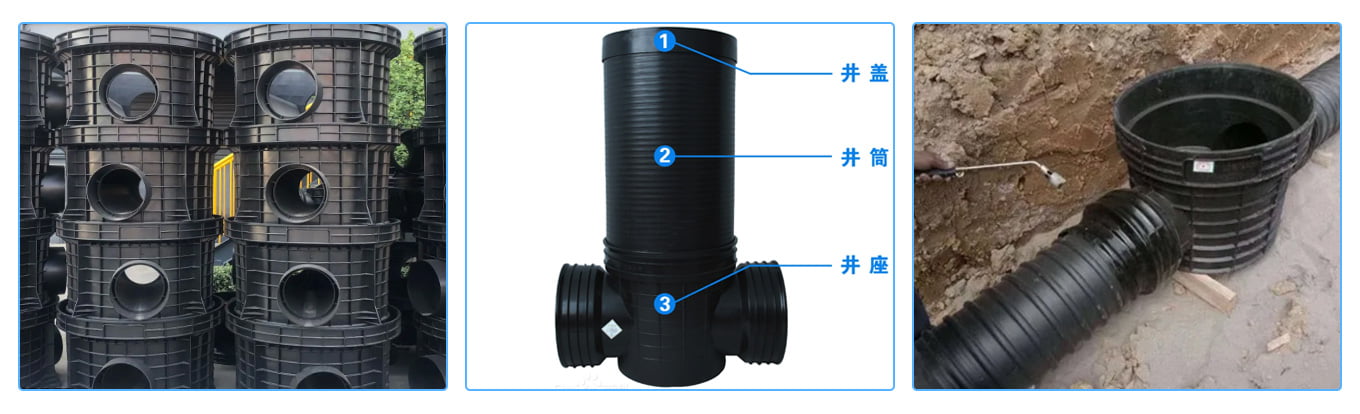

inspection well

The plastic inspection well is composed of a well seat , a well shaft, a well cover and plastic inspection well parts. The inspection well shaft can be made of buried drainage pipes, such as PVC-U double-layer axial hollow pipes, HDPE hollow winding pipes, etc.

According to the number and angle of connecting pipes, there are starting well seats, straight-through well seats, three-way well seats, four-way well seats, 90 -degree elbow well seats, etc. In order to adapt to various drainage conditions, plastic inspection wells are also equipped with inner and outer diameter conversion joints, saddle joints, reducing joints , merging joints, variable angle joints and other matching plastic inspection well spare parts. These parts and well seats are used together to ensure the circulation and sealing of the entire drainage system.

Manhole covers can be cast iron, composite . The quality meets the requirements of the current “Plastic Manholes for Drainage in Building Residential Areas” CJ/T233-2006 . The color is white or gray, and the inner and outer walls of the shaft should be smooth and flat. There should be no bubbles, cracks, depressions, uneven color, or decomposition discoloration lines on the surface. The plastic shaft seat has no cracks or fissures under a static load pressure of 15KN .

The scope of application of plastic inspection wells

( 1 ) Plastic drainage inspection wells with an outer diameter of buried plastic drainage pipes not exceeding 1200mm and a burial depth not exceeding 8m in construction areas (residential areas, public building areas, factories, etc.), urban and rural municipal administration, industrial parks, old city reconstruction, etc. Engineering design, construction and maintenance.

( 2 ) Construction under general soil quality, soft soil soil quality, seasonally frozen soil soil quality soil quality .

( 3 ) Areas with a seismic fortification intensity of 9 degrees or less .

( 4 ) The ground load of the general lane is designed based on the total vehicle weight of 15t (rear wheel pressure 5t ); the ground load of the fire lane is designed based on the total vehicle weight of 30t (rear wheel pressure 6t ).

( 5 ) The groundwater level is designed to be no higher than 1.0m below the ground .

Well diameter series

Table of matching between shaft diameter and drainage pipe diameter and soil covering Unit: mm

| Drainage pipe | Wellbore diameter

(mm) (DN) |

|

| Pipe diameter ( mm ) ( DN ) | Depth of soil covering the top of pipe (m) | – |

| ≤200 | ≤0.8 | OD200 |

| ≤300 | ≤1.0 | OD315 |

| ≤300 | ≤1.5 | OD350 |

| ≤300 | ≤1.8 | OD400 |

| ≤400 | ≤2.0 | OD450 |

| ≤400 | ≤2.5 | OD500 |

| ≤500 | ≤3.0 | OD630 |

| ≤600 | ≤3.5 | OD700 |

| ≤800 | ≤4.0 | OD1000 |

| ≤1000 | ≤6.0 | 0D1000 |

Note: Wellbore diameter (mm) ( DN ) = Inspection well diameter

Component selection

The connection between the well seat and the buried pipeline should use a flexible connection with a rubber sealing ring to adapt to the deformation of the ground seat , etc. Adhesives can only be used for socket-type connections between PVC-U well seats and wellbore diameters of 315mm or less.

Plastic inspection well parts selection:

( 1 ) Inspection well seats with flow grooves should be used on sewage pipes;

( 2 ) For inspection wells on rainwater pipes, their well seats should meet the following requirements:

a . The road rainwater inlet should adopt a well seat with a mud chamber ;

b . When an inspection well with a sedimentation chamber well seat needs to be installed on the rainwater pipe , it should be installed outside the wellbore.

Inspection wells with a diameter greater than or equal to 500mm ;

c . Other rainwater inspection wells can use well seats with flow channels;

Functional advantages

The functional advantages of plastic inspection wells mainly include five aspects: land saving, energy saving, water saving, material saving and environmental protection.

( 1 ), resistant to acid and alkali corrosion, aging, and long service life.

( 2 ) Safety and environmental protection. The material of the plastic inspection well is plastic, which is non-toxic and odorless and can be recycled after use. It is a chemical environmentally friendly building material.

( 3 ), uniform settlement and pressure resistance. The pipe and the well seat are flexibly connected, and the clay in the pipe and the well seat moves together, which solves the problem of uneven settlement caused by the connection between the traditional inspection well and the plastic pipe, and effectively prevents ground collapse.

( 4 ) Convenient and fast construction. The split assembly structure is adopted, and the shaft can be cut and adjusted on site to meet various installation depth requirements, effectively reducing costs, greatly improving construction progress, and shortening the construction period by more than 10-20 times that of traditional inspection wells; and it can be constructed around the clock, which is incomparable to and other cement brick wells .

( 5 ) Efficient drainage. The inner wall is smooth and has a diversion groove, which makes it difficult for dirt to be retained, reducing the possibility of blockage. It has excellent drainage performance, and the rainwater and sewage discharge rate is 1 to 3 times that of traditional inspection wells.

( 6 ) It is light in weight, easy to transport and install, has reliable performance and strong load-bearing capacity; it has strong adaptability and a full range of varieties . It can adjust the wellbore height and drill holes in the barrel and adjust the direction to meet all the needs of engineering installation.

( 7 ) The overall cost is low and the maintenance cost is low, which is more advantageous than traditional inspection wells; it can be recycled and reused, which has huge social benefits.

( 8 ) Good sealing performance and anti-leakage. The flexible connection method is flexible and convenient, and can overcome the harsh construction environment of wind, dust, sand and ash. Good sealing can prevent rainwater and sewage from leaking and leaking, thereby preventing groundwater pollution. It can also overcome the difficulty of repeated insertion due to the increase in road surface height.

( 9 ), save materials. Plastic inspection wells are made of polymer resin of red brick cement, which saves topsoil resources; the specifications used in building communities are reduced, which greatly saves the land space occupied by buried inspection wells.

Reviews

There are no reviews yet.