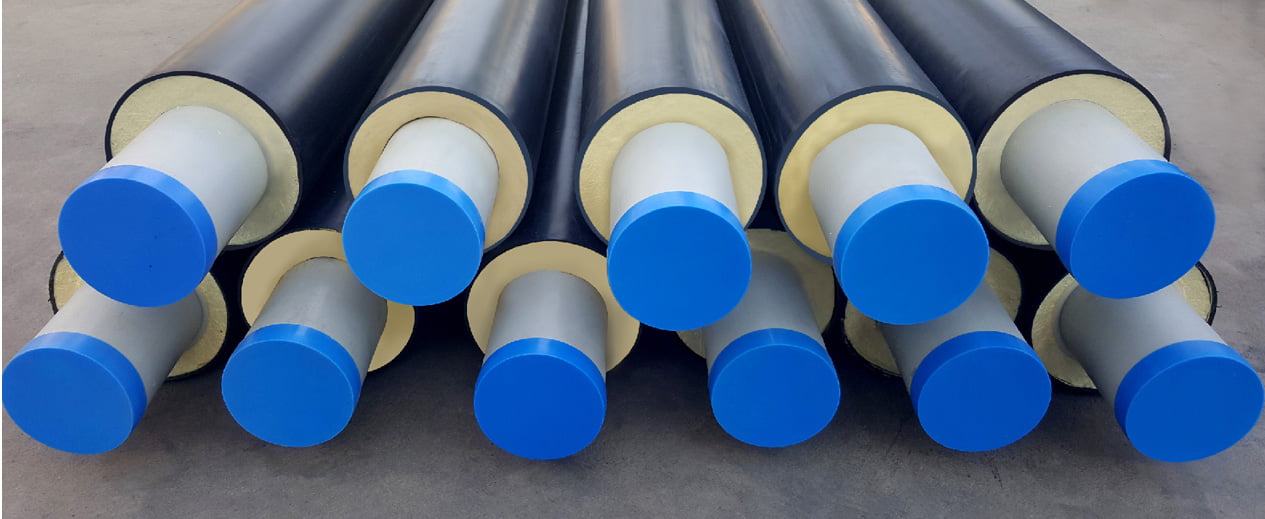

PERT type II pipe

PE-RT II type prefabricated direct buried thermal insulation pipe – high-density polyethylene outer protective pipe polyurethane foam prefabricated direct buried thermal insulation composite plastic (referred to as PE-RT II thermal insulation composite pipe plastic pipe), which is composed of high-density polyethylene outer protective pipe, polyurethane The foam insulation layer and the working tube are tightly integrated.

PE-RT II working pipe can transport hot water below 95° for a long time and has the characteristics of corrosion resistance, service life of up to 50 years, good thermal insulation effect, safe molecular connection, and convenient construction.

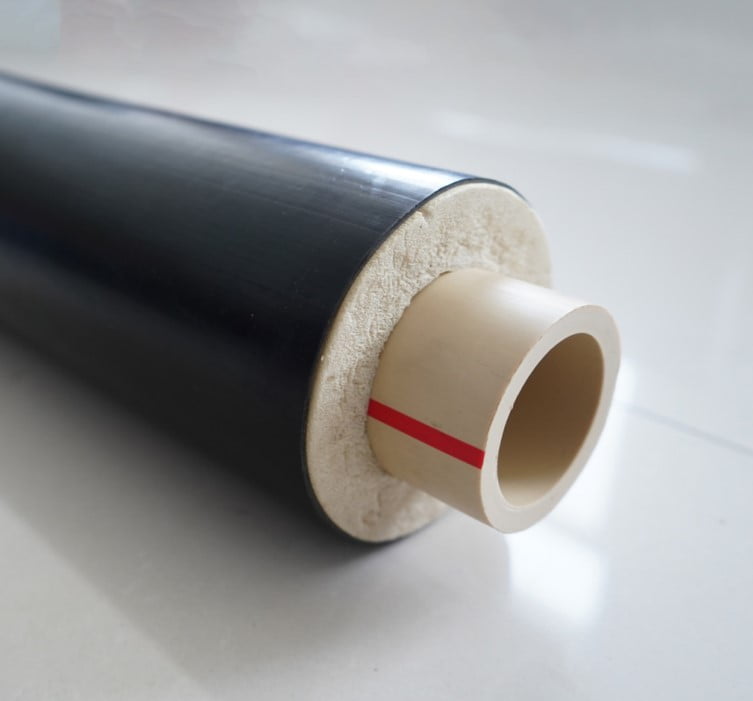

PE-RT II prefabricated direct buried insulated pipe, also known as “PE-RT II insulated composite plastic pipe ” , is composed of high-density polyethylene outer protective layer, polyurethane rigid foam plastic pipe and heat-resistant polyethylene ( PE-RT II ) pipe. PE-RT II prefabricated direct buried insulated pipe has excellent performance and is used in the secondary pipe network system of urban centralized heating. It consists of three parts: outer protective layer, insulation layer and working pipe. The outer protective layer is made of high-density polyethylene ; the insulation layer is made of rigid polyurethane foam plastic ; the PE-RT II working pipe is made of II type heat-resistant polyethylene ( PE-RT II ) special pipe material, which can withstand low and high temperatures of -40 to 110°C .

a . Outer protective pipe: The outer layer of PE-RT II prefabricated direct buried pipe is made of HDPE high-density polyethylene pipe;

b . Insulation layer: made of rigid polyurethane foam. The insulation layer material is rigid polyurethane foam with a density of 60kg/m3 to 80kg/m3 , which fully fills the gap between the PE-RT II type pipe and the casing, and has a certain bonding strength, making the heat-resistant polyethylene ( PE -RT II ) The pipe, outer casing and insulation layer form a solid whole. Polyurethane direct-buried insulation pipe foam has good mechanical properties and thermal insulation properties. It can normally withstand a temperature of 120°C and can withstand a temperature of 180°C through modification or combination with other insulation materials .

c . Working pipe: PE-RT II prefabricated direct buried thermal insulation pipe adopts heat-resistant polyethylene ( PE-RT II ) pipe. The raw material color of the working pipe is transparent, without any masterbatch or filler.

( 1 ) Hygienic performance

The sanitary properties of pipes used for domestic hot water transportation should comply with the requirements of GB/T17219 .

( 2 ) Insulation composite plastic pipe

- Appearance: The appearance of the thermal insulation composite pipe should be clean, and the visible surface should not have defects such as grooves, cracks, depressions, impurities, uneven color, etc. that may affect its performance.

- Pipe end verticality:The outer protective pipe at the end of the insulation composite plastic pipe should be flush with the polyurethane foam insulation layer.

And it should be perpendicular to the axis of the working tube, and the angle error should be less than 2.5° .

- Extrusion deformation and scratches: When the insulation layer is subjected to extrusion deformation, the radial deformation should not be greater than15% of the designed insulation layer thickness .

The scratch depth of the outer protective pipe should not be greater than 10% of the minimum wall thickness of the outer protective pipe , and should not be greater than 1mm .

- The length and deviation of the reserved section at the pipe end:

The length of the non-insulated reserved section at both ends of the working pipe should meet the requirements for the connection of the insulated composite plastic pipe, and the difference in the reserved length at both ends should not be greater than 20mm .

- Foam delamination at pipe end: The insulation layer should be tightly bonded to the working pipe and the outer protective pipe. The radial dimension of the foam delamination of the pipe section should not be greater than2mm , the depth along the axial direction should not exceed 70mm , and the cumulative length in the circumferential direction should not be greater than 1/3 of the circumference .

( 3 ) Surface temperature of outer protective tube

Under operating conditions, the temperature of the outer protective pipe surface should be less than 50°C .

( 4 ) Increase rate of outer diameter of outer protective tube

Before and after foaming of the thermal insulation composite plastic pipe, the increase rate of the outer diameter of the same section at any position of the outer protective pipe should not be greater than 2% .

( 5 ) Maximum axis eccentricity

When the outer diameter of the outer protective tube is not greater than 160mm , the eccentricity of the axis should not be greater than 3.0mm; when the outer diameter of the outer protective tube is greater than

When 160mm , the axis eccentricity should not be greater than 4.5mm .

( 6 ) Axial shear strength

Under the condition of 23℃ , the axial shear strength of the insulation composite plastic pipe should not be less than 0.09MPa .

( 7 ) Ring stiffness

The ring stiffness of the thermal insulation composite plastic should not be less than 4KN/ ㎡.

( 8 ) Impact resistance

Under the condition of -20° , use a 3.0kg falling weight from 2m

Falling from a high place will impact the outer protective pipe, and there should be no visible cracks in the outer protective pipe.

( 9 ) Flexibility

It is suitable for PUPE and PUPB insulation composite plastic pipes with a nominal outer diameter of no more than 50mm . When the minimum bending radius of the outer protective pipe is not greater than 30 times the nominal outer diameter of the outer protective pipe , the insulation layer and the outer protective pipe should not be broken, the out-of- roundness of the outer protective pipe should not be greater than 30% , and the joint part with the outer protective pipe should not be broken. The crack width of the insulation layer should not be greater than 5mm .

( 10 ) Creep properties

The creep ratio should be no less than 5 .

Reviews

There are no reviews yet.