The installation of polyethylene (PE) pipes in a mining environment is a crucial aspect of operational efficiency, safety, and environmental stewardship. PE pipes are known for their flexibility, corrosion resistance, and long service life, making them an ideal choice for transporting fluids and solids in the harsh conditions often found in mining operations. This comprehensive guide aims to walk you through the steps and considerations for effectively installing PE pipes in a mining site.

Understanding PE Pipes

Polyethylene pipes are manufactured from thermoplastic materials, offering a range of diameters and pressure ratings suitable for various mining applications. Key advantages of using PE pipes include:

- Lightweight Construction: Making them easier to handle and install.

- Chemical Resistance: Particularly important in mining operations where the transported fluids may be corrosive.

- Durability: Long lifespan and resistance to impact and stress.

- Flexibility: Allows for easier installation in uneven terrains typical of mining sites.

Planning the Installation

1. Site Assessment

Before installation begins, a comprehensive site assessment is essential. This involves:

- Mapping the Area: Identify the specific routes the pipelines will take, considering existing infrastructure, topography, and environmental factors.

- Soil Analysis: Conducting a geotechnical survey to determine soil type, composition, and potential challenges such as groundwater levels.

- Environmental Impact: Assessing the potential impact of the installation on local flora and fauna, and ensuring compliance with environmental regulations.

2. Regulatory Compliance

Mining operations are subject to a variety of regulations regarding the use and installation of pipelines. Before proceeding, it is crucial to:

- Obtain Necessary Permits: Ensure all required permits are secured from local authorities and regulatory bodies.

- Follow Industry Standards: Adhere to established standards, such as those provided by the American Society for Testing and Materials (ASTM) and the Institute of Gas Engineers and Managers (IGEM).

Material Selection

Choosing the correct type and grade of PE pipe is vital. Factors to consider include:

- Pressure Rating: Select a pipe with an appropriate pressure rating for the application.

- Pipe Diameter: Consider flow requirements and any variations in demand.

- Additives for Performance: In some cases, adding UV stabilizers or anti-oxidants can enhance performance, especially if the pipes will be exposed to sunlight.

Installation Process

1. Site Preparation

The installation area should be cleared and prepared, which includes:

- Clearing Debris: Remove any obstacles, rocks, or vegetation that may hinder installation.

- Trenching: Excavate trenches according to the planned route. The depth and width of the trench should follow local codes, typically allowing for sufficient cover over the pipe.

2. Pipe Installation

With site preparation complete, you can begin the installation of the PE pipes:

- Handling the Pipes: Exercise care when handling the pipes to avoid damage. Use appropriate lifting techniques and equipment.

- Joining Methods: There are several joining methods for PE pipes:

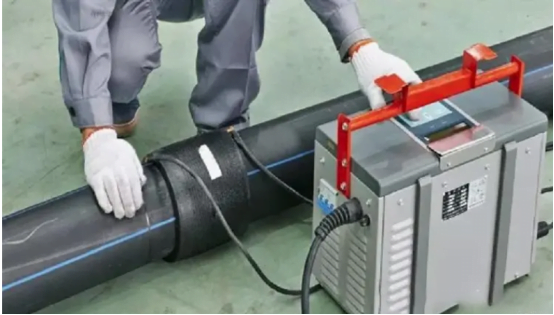

- Electrofusion: Utilizes an electric current to melt the pipe and fitting ends together, creating a strong joint.

- Butt Fusion: Involves heating the ends of two pipe sections until they melt and fuse together.

- Mechanical Fittings: Connects pipe sections using fittings that do not require heat, suitable for quick repairs or modifications.

3. Backfilling

Once the pipes are in place, backfilling the trench should be executed with care to ensure no damage occurs:

- Layering and Compaction: Backfill in layers and compact each layer adequately to create a stable base.

- Avoiding Rocks and Debris: Ensure no sharp objects are left in the soil that could damage the pipeline.

4. Testing the System

After installation, testing is an essential step to verify the integrity and performance of the pipeline:

- Pressure Testing: Conduct a hydrostatic pressure test to ensure that the system can handle the required pressure without leaks.

- Leak Detection Measures: Implement measures like using a vacuum test or conducting a visual inspection along the lengths of the pipe to spot any issues.

5. Final Inspection and Reclamation

Before the project concludes, conduct a final inspection of the installation:

- Compliance Check: Ensure all works comply with regulations and standards.

- Restoration: Rehabilitate the disturbed area, restoring vegetation and soil to minimize environmental impact.

Maintenance Considerations

Once installed, it is crucial to maintain the PE piping system:

- Regular Inspections: Schedule periodic inspections for wear and tear, leaks, and structural integrity.

- Monitoring Flow Rates: Keep an eye on flow rates to identify potential blockages or reductions due to buildup within the pipes.

Conclusion

The installation of PE pipes in a mining site is a process that requires careful planning, adherence to regulations, and skilled execution. By following the guidelines outlined in this post, mining companies can ensure they implement a reliable and efficient piping system that will meet their operational needs while safeguarding the environment. Investing the time and resources into a well-planned installation not only enhances operational effectiveness but also contributes to a sustainable mining future. dcpipe-piping system expert