Ultra high molecular weight polyethylene pipe (UHMW-PE pipe) is a thermoplastic engineering plastic pipe with excellent performance, mainly characterized by:

Extremely high wear resistance: The wear resistance is superior to materials such as polytetrafluoroethylene, nylon, carbon steel, etc., and is 7 times that of steel.

Excellent impact resistance: The impact strength at room temperature is more than 10 times that of PE100, and the lower the ambient temperature, the stronger the impact resistance.

Excellent chemical stability: able to withstand corrosion from various corrosive media and organic solvents, more corrosion-resistant than plastics such as polyethylene, polypropylene, nylon, ABS, etc.

Good self-lubricating properties: With a low coefficient of friction, it reduces the resistance of material movement in pipelines and improves conveying efficiency.

Unique low temperature resistance: performs well in environments ranging from -269 ℃ to+80 ℃.

Non adhesiveness: The surface has strong non adhesiveness, making it difficult to hang materials and reducing blockage.

Long lifespan: The ultra-high aging and embrittlement rates are very slow, and after 50 years of underground use, its mechanical performance only decreases by about 20%.

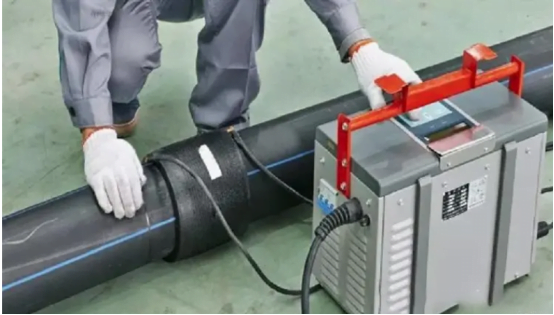

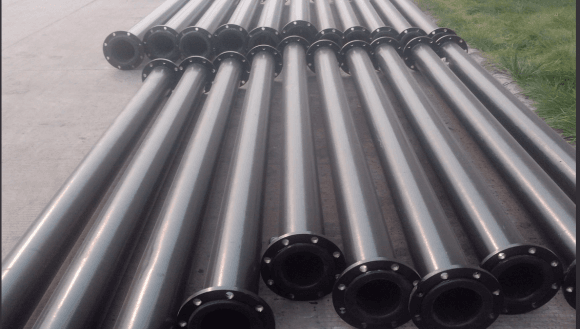

Easy installation: mainly using flange connection, easy to disassemble and install, reducing installation and maintenance costs.

The difference between ultra-high molecular weight polyethylene pipes and high-density polyethylene

The main differences between ultra-high molecular weight polyethylene (UHMW-PE) pipes and high-density polyethylene (HDPE) pipes are reflected in the following aspects:

Molecular weight: The molecular weight of ultra-high molecular weight polyethylene is usually over 2 million, and even up to 3 million, while the molecular weight of high-density polyethylene is between 500000 and 1 million.

Performance: Due to the difference in molecular weight, ultra-high molecular weight polyethylene pipes are superior to high-density polyethylene pipes in terms of wear resistance, impact resistance, and corrosion resistance.

Appearance: Ultra high molecular weight polyethylene has a black and shiny appearance, smooth hand feel, strong toughness, and high tensile strength; High density polyethylene, on the other hand, is relatively dull and has a lower surface glossiness.

Application areas: Ultra high molecular weight polyethylene pipes are more suitable for applications that require high wear resistance, high impact resistance, and high corrosion resistance due to their excellent performance, such as mining, dredging, and other fields; High density polyethylene pipes are more commonly used in fields such as water supply, sewage, and irrigation.

Application of ultra-high molecular weight polyethylene pipes in mining and dredging fields

Mining field: Ultra high molecular weight polyethylene pipes are widely used in transportation systems, equipment manufacturing, and pipeline transportation in the mining industry. Its excellent wear resistance, impact resistance, and self-lubricating properties enable the pipeline to withstand the friction and impact of materials such as ore and mineral powder for a long time, significantly extending the service life of the pipe. At the same time, its corrosion resistance also makes the pipeline perform well when transporting acidic, alkaline, or other corrosive media.

In the field of dredging, ultra-high molecular weight polyethylene pipes are used to clean and transport sediment in waterways. Its wear resistance and impact resistance enable the pipeline to withstand the erosion and wear of materials such as sediment, while its self-lubricating properties also reduce the movement resistance of materials in the pipeline, improving transportation efficiency.

The recognition of ultra-high molecular weight polyethylene pipes worldwide

Ultra high molecular weight polyethylene pipes have been widely recognized and applied worldwide due to their excellent performance and wide range of applications. With the continuous development of technology and improvement of production processes, the performance of ultra-high molecular weight polyethylene pipes will be further enhanced, and their application fields will also continue to expand. At present, this type of pipeline has become one of the preferred transportation materials in many industries, and its market demand continues to grow.

In summary, ultra-high molecular weight polyethylene pipe is a high-performance and widely used thermoplastic engineering plastic pipeline. Its characteristics, differences from high-density polyethylene, applications in mining and dredging fields, and worldwide recognition fully demonstrate its importance and value.

Ultra high molecular weight polyethylene pipes have been widely used worldwide due to their excellent wear resistance, impact resistance, corrosion resistance, and other properties. Specifically, it is widely used in the following countries:

As one of the earliest countries in the world to achieve industrial production of ultra-high molecular weight polyethylene, the United States has accumulated rich experience and technology in the application of ultra-high molecular weight polyethylene pipes. This pipeline is widely used in various fields such as coal, petroleum, chemical, and electricity, and has become an indispensable part of the industrial development in the United States.

Germany: Germany is also in a leading position in the research and production of ultra-high molecular weight polyethylene pipes. Its pipeline products have excellent performance and quality, and are widely used in industries such as food processing, pharmaceutical manufacturing, textile printing and dyeing, meeting the demand for pipeline materials in different fields.

Japan: As an industrial powerhouse in Asia, Japan also attaches great importance to the application of ultra-high molecular weight polyethylene pipes. This pipeline is widely used in Japan for water supply, drainage systems, sewage treatment, and other fields, making important contributions to Japan’s municipal construction and environmental protection.

In recent years, China has also made significant progress in the research and application of ultra-high molecular weight polyethylene pipes. With the increasing attention and support from the government for the new materials industry, more and more enterprises are entering the research and production of ultra-high molecular weight polyethylene pipes. At present, the pipeline has been widely used in various fields such as coal, mining, dredging, chemical industry, and electricity, becoming an important support for China’s industrial development.

In addition, ultra-high molecular weight polyethylene pipes have also been widely used in other industrialized countries such as Russia, Canada, and Australia. These countries, with their advanced industrial technology and development level, have promoted the in-depth application and development of ultra-high molecular weight polyethylene pipes in various fields.

It should be noted that although ultra-high molecular weight polyethylene pipes have been widely used worldwide, there are differences in application fields and market sizes in different countries and regions. Therefore, when promoting and applying ultra-high molecular weight polyethylene pipes, targeted development and promotion should be carried out according to local market demand and actual conditions.

At present, countries actively developing the ultra-high molecular weight polyethylene pipe industry include but are not limited to:

China: As the world’s largest polyethylene production and consumption market, China has shown strong development momentum in the ultra-high molecular weight polyethylene pipe industry. China not only has the world’s most comprehensive ultra-high molecular weight polyethylene industry chain, but also continues to expand production capacity to meet the demand for high-performance pipeline materials in domestic and foreign markets.

The United States: As an industrial powerhouse, the United States has always been at the forefront of research and development, production, and application of ultra-high molecular weight polyethylene pipes. Its advanced production technology and strict quality control standards make the ultra-high molecular weight polyethylene pipes produced in the United States highly competitive in the global market.

Germany: Germany has a profound foundation and strong innovation capability in the chemical industry, and its ultra-high molecular weight polyethylene pipe industry is also constantly developing and growing. German pipeline products have won the trust and praise of global customers for their excellent performance and quality.

Japan: Japan also has rich experience and technological accumulation in the production and application of ultra-high molecular weight polyethylene pipes. Its pipeline products are widely used in various fields, including water treatment, petrochemicals, food processing, etc.

South Korea: South Korea has also shown impressive performance in the ultra-high molecular weight polyethylene pipe industry. With the continuous development of Korean industry and the increasing demand for high-performance pipeline materials, the Korean ultra-high molecular weight polyethylene pipe industry is also continuously expanding its scale.

In addition, countries such as Russia, Canada, and Australia are actively developing the ultra-high molecular weight polyethylene pipe industry to enhance their competitiveness through technological innovation and market expansion. Pipeline companies in these countries are constantly launching new products to meet the demand for pipeline materials in different fields.

In summary, multiple countries worldwide are actively developing the ultra-high molecular weight polyethylene pipe industry, promoting sustainable development through technological innovation and market expansion.

The Chinese market holds a positive and optimistic attitude towards ultra-high molecular weight polyethylene pipes. The following is a detailed analysis of how the Chinese market views ultra-high molecular weight polyethylene pipes:

Market demand growth

Consumption increase: In recent years, the consumption of ultra-high molecular weight polyethylene in China has continued to grow. According to data, the total consumption of ultra-high molecular weight polyethylene in China in 2023 is about 432200 tons, a year-on-year increase of 54.36%. It is expected that by 2024, the apparent consumption will reach 467100 tons.

Widely applicable fields: Ultra high molecular weight polyethylene pipes have been widely used in multiple fields due to their excellent wear resistance, impact resistance, corrosion resistance, and other properties. Especially in the fields of mining, dredging, chemical engineering, and electricity, the demand for ultra-high molecular weight polyethylene pipes is particularly strong.

Industrial policy support

National policy guidance: The Chinese government attaches great importance to the development of the new materials industry and has formulated a series of industry support policies to promote the research and application of high-performance materials, including ultra-high molecular weight polyethylene. These policies provide strong guarantees and support for the development of the ultra-high molecular weight polyethylene pipe industry.

Encouragement of Technological Innovation: National policies encourage enterprises to increase research and development investment, engage in technological innovation and industrial upgrading. This promotes the continuous optimization and improvement of ultra-high molecular weight polyethylene pipes in terms of performance, quality, cost, and other aspects.

Market competition pattern

Intense market competition: With the continuous expansion of the ultra-high molecular weight polyethylene pipe market, more and more companies are entering this field. The market competition is becoming increasingly fierce, and enterprises need to enhance their competitiveness by continuously improving product quality, reducing production costs, and optimizing services.

Brand effect highlights: In the fierce market competition, some well-known brands have won the trust and praise of customers with their excellent product performance and high-quality service. The brand effect is gradually becoming prominent in the ultra-high molecular weight polyethylene pipe market.

Future Development Trends

Market demand continues to grow: With the rapid development of the Chinese economy and the acceleration of industrialization, the demand for high-performance pipeline materials will continue to increase. As a leader among them, the market demand for ultra-high molecular weight polyethylene pipes is expected to continue to maintain stable growth.

Technological innovation and industrial upgrading: In the future, China’s ultra-high molecular weight polyethylene pipe industry will continue to increase research and development investment, carry out technological innovation and industrial upgrading. This will further enhance the performance and quality level of the product, meeting the constantly changing demands of the market.

Green and environmentally friendly development: With the continuous improvement of environmental awareness and the deepening of the concept of green and sustainable development, the ultra-high molecular weight polyethylene pipe industry will also pay more attention to environmental protection and sustainable development. By adopting green synthesis methods and optimizing production processes, the impact on the environment can be reduced.

In summary, the Chinese market holds a positive and optimistic attitude towards ultra-high molecular weight polyethylene pipes. In the future, with the continuous growth of market demand and the promotion of technological innovation, China’s ultra-high molecular weight polyethylene pipe industry is expected to usher in a broader development prospect.