Tin, a versatile and significant metal, has been an essential material for various industries due to its unique properties, such as resistance to corrosion and high malleability. From electronics to packaging, tin finds applications in countless products, making its mining an economically important activity. This blog post will provide an extensive overview of the tin mining process, the geographic distribution of tin deposits, and key corporations engaged in tin extraction and production. dcpipe pipeline expert

The Tin Mining Process

1. Exploration

The journey of tin mining begins with exploration. Geologists assess the potential locations for tin deposits using a variety of methods, including aerial surveys, geological mapping, and soil sampling. Advanced techniques like geophysical surveys and geochemical analysis are also employed to identify promising sites. The exploration phase is crucial as it helps determine the viability of the mine, including the quantity and quality of tin ore available.

2. Evaluation and Feasibility Studies

Once potential reserves are identified, mining companies perform feasibility studies to evaluate economic viability. These studies involve analyzing the estimated costs of mining versus the anticipated profitability. Key factors considered include the mining techniques to be used, the required infrastructure, environmental impact assessments, and market conditions for tin. This stage is critical for attracting investors and securing funding for further development.

3. Development and Environmental Management

If a project is deemed feasible, development begins. This phase includes the construction of necessary infrastructure, such as access roads, processing facilities, and waste management systems. Environmental management plays a pivotal role in the development stage, ensuring compliance with regulations aimed at minimizing the ecological impact of mining activities. This may involve reforestation, managing water resources, and maintaining biodiversity in the surrounding ecosystem.

4. Extraction

The extraction of tin ore, primarily cassiterite (SnO2), is a complex process involving several methods, including:

- Alluvial Mining: This method is commonly used for extracting tin from riverbeds and floodplains. Natural forces wash away lighter materials, allowing miners to collect heavier tin-rich ore deposits using simple tools or machinery. Alluvial mining is labor-intensive and is primarily conducted in artisanal and small-scale mining operations.

- Open-Pit Mining: When tin deposits are located near the surface, open-pit mining becomes the preferred method. It involves removing overburden to access the ore body. Heavy machinery, such as excavators and trucks, are used to efficiently extract large volumes of ore.

- Underground Mining: For deeper deposits, underground mining techniques are utilized. This method requires more sophisticated infrastructure and involves creating tunnels to access the ore. Although this method can be costly, it is often necessary for economically viable operations.

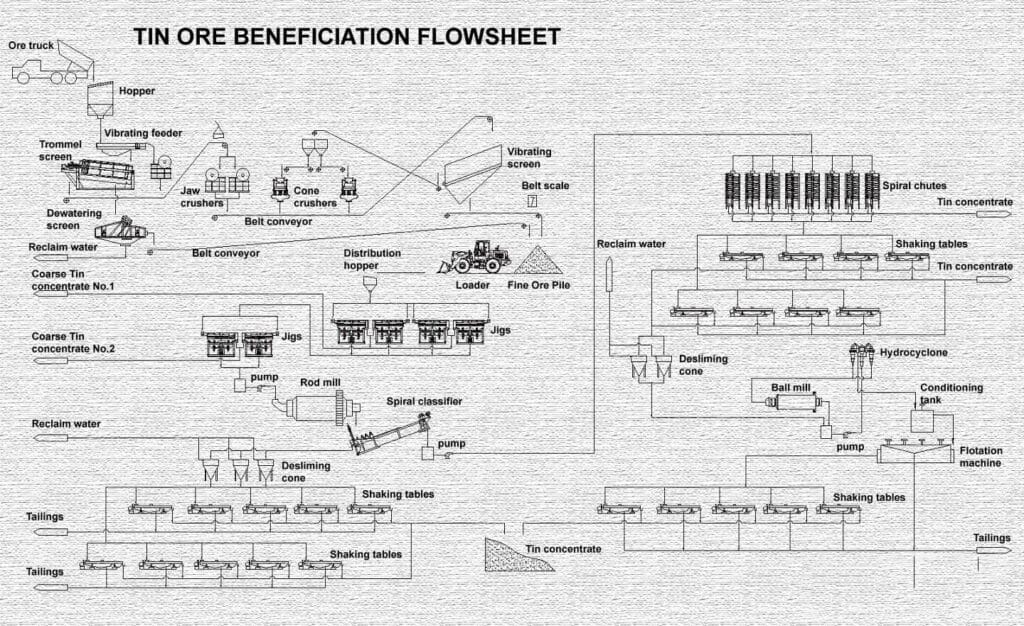

5. Processing and Refining

Once extracted, tin ore undergoes various processing methods to separate the tin from other minerals. Common processes include crushing the ore, followed by concentration methods such as gravity separation, flotation, or magnetic separation. After concentration, the tin-rich material is smelted to produce refined tin metal. This step involves heating the concentrate to remove impurities, resulting in various grades of tin suitable for different applications.

6. Transportation and Marketing

After processing, the refined tin is packaged and transported to manufacturers worldwide. Distribution occurs through a network of suppliers, traders, and markets, all of which play roles in the global tin supply chain. Proper marketing strategies are vital to reach end-users effectively, as tin is a globally traded commodity.

Geographic Distribution of Tin Deposits

Tin deposits are geographically distributed across the globe, with notable concentrations found in specific regions.

- Southeast Asia: Countries like Indonesia and Malaysia are renowned for their extensive tin reserves. The Malaysian state of Perak and the Indonesian island of Bangka-Belitung are significant sources of alluvial tin.

- South America: Bolivia hosts some of the world’s largest hard rock tin deposits, primarily located at high elevations in the Andes. Brazil also has significant tin production, particularly in the Minas Gerais state.

- Africa: Countries such as Nigeria and Rwanda have emerging tin mining operations, focusing on both alluvial and hard rock deposits. These regions are increasingly becoming important players in the global tin market.

- Australia: Australia remains a reliable source of tin, predominantly through hard rock mining. Significant deposits are concentrated in Tasmania, particularly in the region surrounding Rosebery and the West Coast.

- China: As the largest producer of tin worldwide, China boasts vast reserves, particularly in the provinces of Yunnan and Jiangxi. Chinese companies dominate both local and international markets, playing a crucial role in global tin supply chains.

Major Tin Mining Companies

A variety of companies are involved in tin mining and production globally. Some of the most notable include:

1. PT Timah (Persero) Tbk (Indonesia)

PT Timah is one of the largest tin producers worldwide, with extensive operations in Indonesia. The company is well-known for its high-quality tin production and operates both alluvial and offshore mining operations.

2. Malaysia Smelting Corporation Berhad (Malaysia)

Malaysia Smelting Corporation is a leading producer of tin in Malaysia and focuses on refining and smelting operations. The company holds a substantial market share and is known for its commitment to sustainable mining practices.

3. Yunnan Tin Company Limited (China)

As the largest tin producer in China, Yunnan Tin Company is a state-owned enterprise with deep roots in the region’s tin mining industry. The company’s extensive operations make it a significant player in the global tin market.

4. China Tin Corporation Limited (China)

Another major player in China’s tin sector, China Tin Corporation is involved in both mining and metal processing. The company is recognized for its technological advancements in tin extraction and processing.

5. metal concentrates (Bolivia)

Metal Concentrates, based in Bolivia, is a leading force in the South American tin mining industry. The company’s operations focus on sustainable practices and responsible sourcing of tin ore.

Conclusion

Tin mining is a complex and multifaceted process that involves numerous stages from exploration to production and distribution. Its global distribution and importance in various sectors highlight the significant role the metal plays in our daily lives. With a diverse array of companies and geographic locations involved in tin mining, the industry continues to evolve and adapt to changing market demands and environmental standards.

As the demand for tin remains strong, driven by its integral role in technology and manufacturing, the need for sustainable and responsible mining practices will be paramount. The ongoing advancements in mining technologies and a growing focus on environmental stewardship will shape the future of tin mining, ensuring that this vital resource is available for generations to come. dcpipe pipeline expert