Bauxite mining is a critical industrial process that plays a vital role in the global aluminum production chain. As the primary ore of aluminum, bauxite holds significant economic and strategic importance. In this blog post, we will conduct a comprehensive and detailed examination of the bauxite mining process, the geographic distribution of bauxite deposits worldwide, and highlight some of the major companies involved in bauxite mining. dcpipe pipeline expert

Understanding Bauxite

Before delving into the mining processes, it is essential to understand what bauxite is. Bauxite is a sedimentary rock with a high aluminum content, primarily composed of aluminum oxides. It invariably contains other minerals such as iron oxides, silica, and titanium dioxide. The formation of bauxite occurs through the weathering of aluminum-rich rocks under tropical and subtropical climates, leading to the leaching of some elements and the accumulation of aluminum-rich minerals.

Bauxite Mining Process

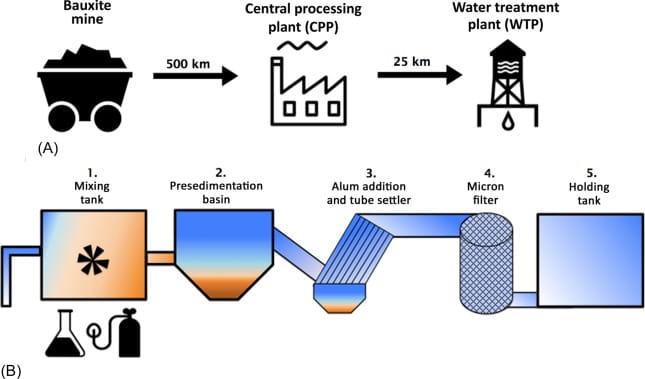

The bauxite mining process involves several stages, which can be broadly categorized into exploration, mining, transportation, and processing.

1. Exploration

Exploration is the first step in the bauxite mining process. It involves geological surveys and drilling campaigns to determine the presence and quantity of bauxite ore. Geologists employ various techniques such as geophysical surveys, drilling, and sampling to evaluate the ore quality and deposit size. The exploration phase is crucial for determining the economic viability of mining in a particular region.

2. Extraction

Once a bauxite deposit has been confirmed, the extraction process can begin. Bauxite is typically mined through open-pit mining methods due to its shallow deposits. The actual extraction process involves:

- Overburden Removal: Stripping away the topsoil and waste rock to access the bauxite ore beneath.

- Mining: The bauxite is then extracted using excavators and trucks. This process generally can produce several million tons of ore annually, depending on the mine’s scale.

- Ordnance Management: In many regions, specific environmental regulations must be adhered to, governing how overburden and waste materials are managed to minimize ecological impact.

3. Transportation

Upon extraction, bauxite is transported to processing facilities or export terminals. The choice of transportation method depends on the location and infrastructure available. Bauxite is often transported by:

- Truck: For closer sites, trucks are the most common method.

- Rail: In regions with developed rail networks, trains provide efficient transport for larger volumes.

- Barge/Ship: For mines located near coastlines or rivers, shipping may occur directly to smelters or distribution centers.

4. Processing

The final stage in the bauxite mining process is the refining of bauxite into alumina through the Bayer process. This involves:

- Digestion: Crushing the bauxite and mixing it with a hot caustic soda solution to extract aluminum oxide.

- Clarification: The slurry is allowed to settle, separating impurities from the aluminum-bearing solution.

- Precipitation: The aluminum hydroxide is precipitated from the solution and then washed to remove residual caustic soda.

- Calcination: Finally, the aluminum hydroxide is heated in rotary kilns to produce alumina, which can subsequently be transformed into aluminum through electrolytic reduction.

Geographic Distribution of Bauxite

Bauxite deposits are widely distributed across the globe, with several countries emerging as significant producers. The primary regions of bauxite distribution include:

- Australia: Leading the world in bauxite production, Australia boasts the largest reserves and operates some of the largest mines, including the Weipa and Gove mines. Its favorable mining conditions and infrastructure contribute significantly to its status as a leading exporter.

- Brazil: Another major player in the global bauxite market, Brazil has considerable deposits, primarily located in the Amazon basin. The country is also known for its environmental regulations, which can influence mining operations.

- Guinea: This West African nation has the world’s largest reserves of bauxite, particularly in the Sangarédi and Friguia regions. Rapid developments in mining infrastructure have positioned Guinea as a fast-growing exporter.

- Jamaica: Historically significant in bauxite mining since the 1950s, Jamaica has rich deposits that are strategically mined, with significant contributions to the country’s economy.

- India: With growing demand for aluminum, India is witnessing an increase in bauxite mining activities, particularly in states like Odisha and Chhattisgarh.

- Russia: Russia possesses substantial reserves of bauxite, primarily in the Ural Mountains region and the Siberian region, contributing to its aluminum production capabilities.

Major Bauxite Mining Companies

A handful of multinational companies dominate the bauxite mining sector. These organizations play critical roles in the bauxite supply chain from extraction to refining. Some of the key players include:

- Rio Tinto: An Anglo-Australian mining corporation, Rio Tinto operates several prominent bauxite mines globally, including operations in Australia and Guinea. The company is recognized for its strong commitment to sustainability and responsible mining practices.

- Alcoa Corporation: Based in the United States, Alcoa is a major producer of bauxite and alumina, with operations in Australia, Brazil, and other jurisdictions. Alcoa invests heavily in technology for sustainable practices in mining and refining.

- Emirates Global Aluminium (EGA): As the largest industrial company in the UAE, EGA not only operates bauxite mines but also processes the ore into alumina and aluminum, contributing significantly to the nation’s economy.

- Gencor (South32): South32 is involved in bauxite mining operations in Australia. The company operates the Worsley Alumina operation, reflecting its commitment to innovation and sustainability in the mining sector.

- China Hongqiao Group: Representing one of the largest aluminum producers globally, this Chinese company is heavily involved in mining and processing bauxite within China and abroad.

Conclusion

Bauxite mining is a multifaceted process that requires meticulous attention to environmental stewardship, economic planning, and technological advancement. As the global demand for aluminum continues to rise, bauxite mining will remain a critical sector. Understanding the mining processes, geographic distributions, and participating companies helps stakeholders navigate the complexities of the industry, highlighting the significance of sustainable practices and responsible resource management for future generations.

Through ongoing innovation and an increased focus on environmental considerations, the bauxite mining industry can sustain its role as a backbone of the aluminum production process while contributing to global economic growth. dcpipe pipeline expert