In the realm of engineering and fluid dynamics, particularly when discussing pressure vessels, pipelines, and various systems that handle fluids, the terms nominal pressure, working pressure, and design pressure often arise. These concepts are critical for ensuring safety, functionality, and efficiency in engineering applications. This blog post aims to explicate these terms, highlighting their definitions, significance, and the distinctions among them.

1. Defining Key Terms

Nominal Pressure

Nominal pressure, sometimes referred to as “rated pressure,” is a designation used to categorize the pressure capacity of piping, fittings, and other equipment. It serves as a standardized metric to indicate the maximum allowable pressure under specific conditions. While nominal pressure is often represented in terms of gauge pressure (the pressure relative to atmospheric pressure), it can also be specified in absolute terms.

The significance of nominal pressure lies in its role in standardization. It streamlines the classification of pressure ratings among various components, facilitating the selection of appropriate materials and designs for specific applications. In engineering codes and standards, nominal pressure ensures a level of uniformity, making it easier for engineers and manufacturers to communicate specifications.

Working Pressure

Working pressure is defined as the maximum pressure that a system is expected to operate under normal working conditions. It is derived from practical usage scenarios and represents a more realistic and applicable pressure level than nominal pressure. Instead of being a theoretical maximum, working pressure takes into account factors such as temperature fluctuations, operating conditions, and potential variations that might arise during regular use.

Understanding working pressure is crucial for engineers and operators, as it influences the choice of materials for construction and maintenance schedules. Systems are typically designed with a working pressure that provides a margin for safety above the expected operational conditions, ensuring reliable performance without risking equipment failure or safety hazards.

Design Pressure

Design pressure is the pressure used in the design of a system’s components. This term is specifically related to the engineering and structural aspects of construction. Design pressure considers the maximum pressure that components should withstand, accounting for safety factors and potential pressure surges beyond normal operating conditions.

When establishing design pressure, engineers will analyze various factors, including potential pressure spikes, temperature variations, and external influences such as weather or seismic activity. This comprehensive analysis helps ensure the integrity and safety of the design throughout its operational lifespan.

2. Distinctions and Relationships Among the Three Pressures

Key Differences

While nominal pressure, working pressure, and design pressure are related concepts in the context of pressure systems, they serve distinct purposes:

- Nominal Pressure is more about standardization and classification. It provides a reference point for manufacturers and users, facilitating easier communication regarding the capabilities of components.

- Working Pressure reflects the practical operating conditions of the system. It is a critical factor that influences the everyday performance and operational safety of the equipment.

- Design Pressure involves the detailed engineering considerations that ensure a system can withstand anticipated maximums, including unforeseen circumstances. It emphasizes safety and structural integrity and is often higher than both nominal and working pressures to provide adequate safety margins.

Interrelationships

Despite their differences, these pressures are interrelated. For example, when designing a pressure vessel, engineers will typically start with the nominal pressure rating of the materials being used. They will then determine the working pressure based on anticipated operational scenarios. Finally, they will establish a design pressure that accommodates variations and adds safety margins to ensure that the vessel can withstand conditions beyond normal operations.

Successful engineering solution relies on a carefully calculated balance among these pressures, as they ultimately affect the overall reliability, safety, and function of the system.

3. Practical Applications

Understanding these concepts is essential across various industries, including oil and gas, chemical processing, water treatment, and many others where pressure systems are employed. Here are some practical applications of these pressures:

Oil and Gas Industry

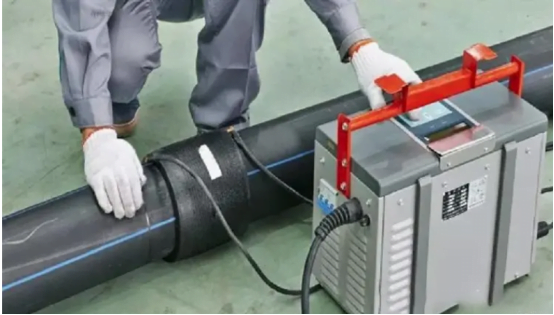

In the oil and gas sector, pipelines and storage tanks must be designed to handle both the intended working pressure and potential pressure surges that may occur during operations. Therefore, engineers must consider design pressure essential to ensuring the structural integrity of the system and preventing catastrophic failures.

Water Treatment Facilities

Water treatment facilities manage various processes under pressure, from chemical dosing to filtration. The working pressure must align with the operational needs of the system to maintain water quality, while design pressure ensures that all components can withstand potential increases in pressure due to equipment failures or backups.

Chemical Processing

In chemical processing, understanding the differences between these pressures is critical for the safety and efficiency of reactions that may generate significant heat and pressure. Design systems that incorporate these pressures appropriately minimize risks associated with overpressurization, leading to safer environments for workers.

Conclusion

Understanding the concepts of nominal pressure, working pressure, and design pressure is vital for professionals in engineering fields that involve pressure systems. These terms not only represent critical safety factors but also underpin design considerations that ensure the functionality and durability of various systems. By recognizing and properly utilizing these pressures, engineers can create safer, more efficient designs that stand the test of time. dcpipe-piping system expert