PE pipes and PE water supply pipes are widely used in urban water supply and gas transmission due to their excellent properties like corrosion resistance, low-temperature resistance, lightweight, and good toughness. Efficiently and safely connecting these pipes to valves is a significant technical challenge. Below are the common connection methods:

Hot-Melt Connection Method

Hot-melt connection involves heating the pipe and fittings to a specific temperature using specialized heating tools, melting them, and quickly connecting them.

Advantages: Provides a strong, well-sealed connection, particularly suitable for larger diameter pipes.

Applications: Commonly used for pipe diameters between DN20-DN110. For DN20-DN63, hot-melt socket welding is used, while for DN75-DN110, either hot-melt socket welding or hot-melt butt welding may be chosen based on site conditions.

Considerations: It’s crucial to strictly control the welding time and temperature to ensure a high-quality connection.

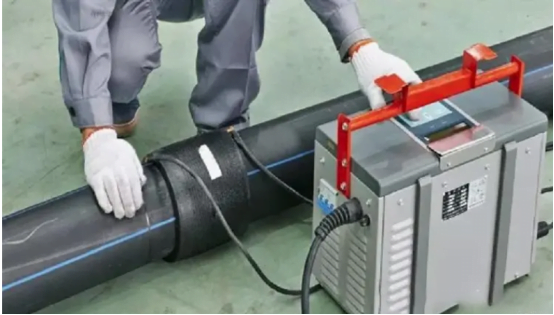

Electrofusion Connection

Electrofusion connection uses electric heating coils to heat the pipe and fittings for connection.

Advantages: Easy and quick to operate, and the connected pipe can be used immediately.

Applications: Typically applied to pipe diameters ranging from DN50 to DN800. It’s also suitable for small-diameter pipes like DN25, DN32 in residential or rural water supply systems where hot-melt tools are inconvenient.

Considerations: Proper control of heating time and temperature is necessary to ensure a reliable connection.

Flange Connection

Flange connection is used primarily to connect PE pipes to metal pipes or valves.

Process: This method involves using bolts, nuts, and other fasteners to tightly connect the flange pieces.

Applications: Suitable for larger diameter PE pipes, typically in the range of DN63-DN1200.

Other Connection Methods

Flexible Socket Connections: Available in the market for specific requirements. The appropriate method should be chosen based on the pipe diameter, working pressure, and actual use environment.