Introduction

In the ever-evolving landscape of pipeline technology, the PE RT (Polyethylene Reticulated) pipeline system has emerged as a frontrunner, boasting significant advantages in durability, flexibility, and safety. As industries pivot toward more efficient and sustainable solutions, understanding the intricacies of PE RT pipelines is imperative for engineers, project managers, and decision-makers in various sectors. This blog post aims to provide a comprehensive examination of PE RT pipeline systems, exploring their manufacturing process, properties, applications, and benefits.

What is PE RT Pipeline?

PE RT pipelines are composed of a specialized form of polyethylene that undergoes a cross-linking process to enhance its physical properties. The term ‘PE’ stands for polyethylene, a ubiquitous plastic known for its versatility, while ‘RT’ refers to the reticulated or cross-linked nature of the polymer structure. This modification significantly enhances the material’s resistance to heat, pressure, and chemical exposure, allowing PE RT pipelines to be used effectively in a wide range of applications from gas distribution to potable water transportation.

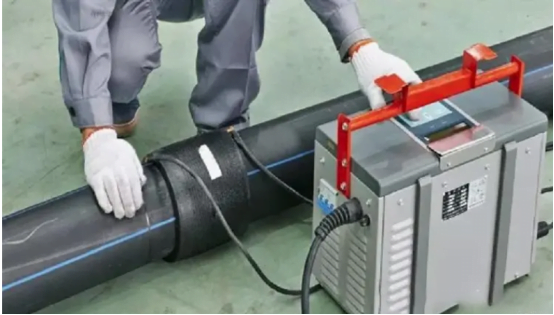

Manufacturing Process

The manufacturing process of PE RT pipelines involves several key steps:

1. Material Selection

The process begins with selecting high-quality polyethylene resin. Different grades of polyethylene can be utilized depending on the specific requirements of the pipeline application, particularly in terms of temperature and pressure resistance.

2. Cross-Linking

The cornerstone of PE RT pipeline technology is the cross-linking process, typically achieved through thermal or chemical means. The most common methods include:

- Peroxide Cross-Linking: In this method, a peroxide compound is added to the polyethylene during the extrusion process, initiating a chemical reaction that forms covalent bonds between polymer chains.

- Silane Cross-Linking: This method utilizes a silane compound that enhances the molecular structure of the polyethylene when exposed to moisture. This can result in a more flexible and durable pipeline.

3. Extrusion

The cross-linked polyethylene is then extruded into the desired pipe shape. This process is critical as it determines the final diameter, wall thickness, and length of the pipeline. Advanced extrusion technology ensures a uniform and consistent product.

4. Testing and Quality Assurance

Post-manufacturing, rigorous testing is conducted to ensure the pipelines meet relevant industry standards. This includes pressure testing, ductility tests, and assessments for resistance to environmental factors.

Properties of PE RT Pipelines

PE RT pipelines exhibit a multitude of advantageous properties, setting them apart from conventional pipeline materials:

1. Chemical Resistance

PE RT is highly resistant to a wide range of chemicals, making it suitable for transporting corrosive substances without the risk of material degradation.

2. Flexibility

The inherent flexibility of polyethylene allows PE RT pipes to be easily installed in various terrains and conditions, minimizing the need for extensive civil engineering works.

3. Temperature Tolerance

PE RT pipelines can withstand elevated temperatures, with some formulations capable of functioning effectively at temperatures up to 70°C or higher, making them ideal for hot water applications.

4. Low Friction Coefficient

The smooth interior surface of PE RT pipelines reduces friction losses, leading to improved flow rates and energy efficiency for fluid transport.

5. Lightweight

Compared to traditional piping materials like steel or concrete, PE RT pipelines are significantly lighter, facilitating easier handling and installation, ultimately reducing labor costs.

Applications of PE RT Pipelines

Given their robust properties, PE RT pipelines find diverse applications across several industries:

1. Water Supply Systems

PE RT pipelines are extensively used in municipal water supply systems due to their corrosion resistance and ability to maintain water quality.

2. Natural Gas Distribution

The flexibility and pressure resistance of PE RT make it an optimal choice for natural gas distribution networks, ensuring safe and efficient transport.

3. Wastewater Management

PE RT pipelines are utilized in both sewage and stormwater applications, where their resistance to various chemicals and low permeability ensure effective containment and reduced leakage.

4. Industrial Applications

Industries such as chemicals, food processing, and pharmaceuticals leverage PE RT pipelines for their ability to transport various substances safely under pressure and temperature variations.

Advantages of PE RT Pipelines

The adoption of PE RT pipelines presents numerous advantages over traditional materials, including:

1. Cost-Effectiveness

Despite potential higher upfront costs, the longevity and reduced maintenance needs of PE RT pipelines result in lower lifecycle costs.

2. Sustainability

Polyethylene, being recyclable, and the durability of PE RT pipelines contribute to a sustainable approach to infrastructure development. The reduced need for replacements and repairs also minimizes environmental impact.

3. Enhanced Safety

The ability to handle high pressure and temperature reduces the risk of leaks and bursts, enhancing the overall safety of pipeline operations.

4. Improved Reliability

Tested rigorously, PE RT pipelines exhibit a high degree of reliability, reducing downtime and disruption in service.

Conclusion

PE RT pipelines represent a significant advancement in pipeline technology, offering a combination of flexibility, durability, and resistance to adverse conditions that traditional materials struggle to match. As industries continue to prioritize sustainability and cost efficiency, the utilization of PE RT pipelines is expected to grow. Understanding this innovative material is crucial for professionals involved in infrastructure planning and development. By leveraging the benefits of PE RT technology, stakeholders can ensure that their pipeline systems are not just functional but also capable of meeting the demands of the future.

In a world increasingly focused on sustainable development, the PE RT pipeline stands out as a testament to engineering ingenuity—one that promises to revolutionize how we think about fluid transport for generations to come. dcpipe-piping system expert