In the realm of plumbing and construction, the choice of piping material is critical for determining the efficiency, longevity, and safety of water transport systems. Among the various materials available, five common types of piping are often utilized: PB (Polybutylene), PE (Polyethylene), PVC (Polyvinyl Chloride), PERT (Polyethylene Raised Temperature), and PPR (Polypropylene Random Copolymer). Each of these materials comes with its distinct properties, advantages, disadvantages, and applications. This blog post aims to elucidate the differences among these pipes, aiding decision-makers in selecting the most suitable option for their specific needs.

1. Polybutylene (PB) Pipes

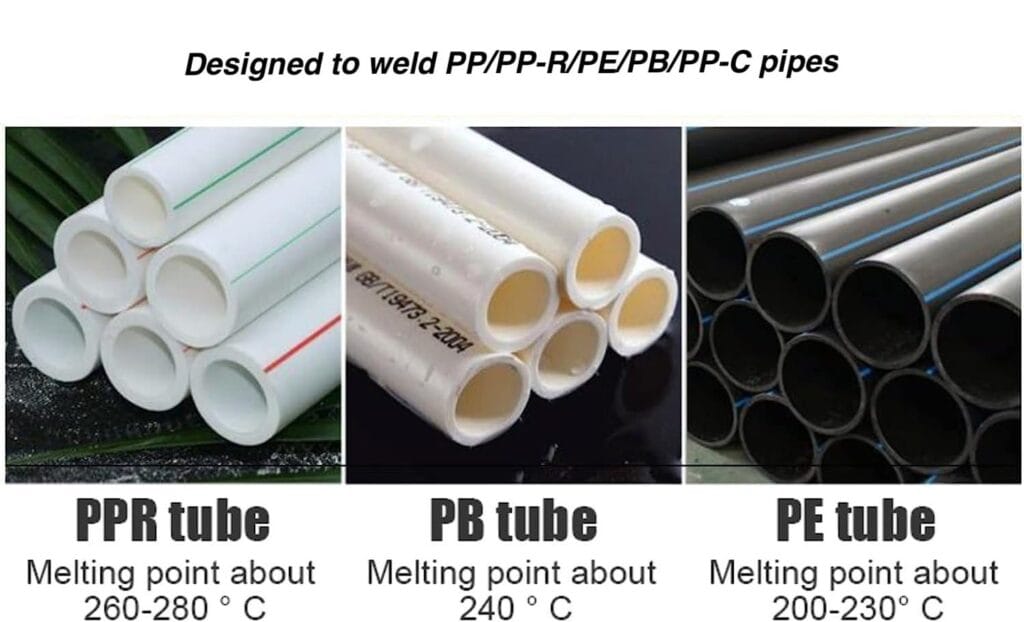

Polybutylene (PB) previously gained popularity in residential plumbing systems, especially from the 1970s to the mid-1990s due to its affordability and ease of installation. PB is a flexible plastic and can be easily shaped to accommodate various plumbing designs.

Advantages:

- Flexibility: PB pipes can bend around corners without needing fittings, reducing potential leak sites.

- Ease of Installation: Lightweight and flexible, PB is simple to transport and install, leading to lower labor costs.

Disadvantages:

- Durability Issues: PB has been linked to numerous plumbing failures due to its susceptibility to degradation from chlorine in drinking water, leading to leaks and bursts.

- Legal and Financial Risks: Many homes built using PB have faced litigation, resulting in a decline in its usage and availability.

Applications:

Due to widespread failures and concerns about durability, PB is now rarely recommended for new installations. Existing systems may require replacement with more reliable materials.

2. Polyethylene (PE) Pipes

Polyethylene (PE) is a versatile thermoplastic used extensively across various sectors, including water distribution, gas supply, and agricultural applications. It is known for its resilience and high resistance to impact and corrosion.

Advantages:

- Chemical Resistance: PE is resistant to many chemicals, making it an excellent choice for transporting potable water and industrial applications.

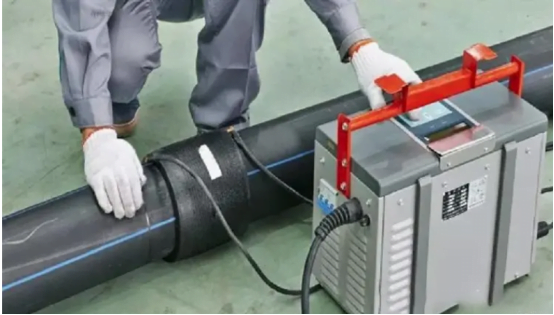

- Flexibility and Weldability: PE pipes can be joined through fusion or mechanical fittings, ensuring strong and leak-proof connections.

Disadvantages:

- Temperature Limitations: PE can become brittle at low temperatures and is not suitable for high-temperature applications.

- UV Sensitivity: PE pipes can degrade when exposed to sunlight unless properly protected.

Applications:

PE pipes are commonly employed in water supply systems, irrigation, and gas distribution lines due to their flexibility, durability, and resistance to corrosion.

3. Polyvinyl Chloride (PVC) Pipes

PVC (Polyvinyl Chloride) is one of the most widely used plastic piping materials due to its versatility, affordability, and durability. It is primarily utilized in drainage, waste, and vent systems, as well as in pressure applications.

Advantages:

- Cost-Effective: PVC is among the least expensive types of piping, making it an economical choice for many plumbing projects.

- Corrosion Resistance: PVC does not corrode like metal pipes, thus having a longer lifespan in many cases.

Disadvantages:

- Brittleness: PVC can become brittle over time, especially under temperature fluctuations or UV exposure.

- Limited Temperature Range: PVC is not recommended for hot water applications, as high temperatures can deform the material.

Applications:

Commonly used for both residential and commercial plumbing, PVC is ideal for waste and vent systems, irrigation, and electrical conduit applications.

4. Polyethylene Raised Temperature (PERT) Pipes

PERT is a type of polyethylene designed to be used at elevated temperatures. It is a relatively new material that combines the advantageous features of both PE and PVC.

Advantages:

- High-Temperature Resistance: PERT can withstand higher temperatures than standard polyethylene, making it suitable for hot water systems.

- Flexibility and Light Weight: Similar to PE, PERT is lightweight and offers flexibility, facilitating easier installation.

Disadvantages:

- Limited Jointing Methods: While PERT can be fused like PE, the techniques may not be as standardized, potentially limiting installer options.

- Cost: PERT can be more expensive than traditional PE or PVC.

Applications:

PERT is typically used in heating systems, underfloor heating, and as a main pipe in domestic hot water distribution.

5. Polypropylene Random Copolymer (PPR) Pipes

PPR pipes have witnessed increasing usage in plumbing systems globally due to their reliability and thermal resistance. They are characterized by their smooth internal surface, which minimizes fluid friction and prevents build-up.

Advantages:

- Excellent Thermal Resistance: PPR can handle high temperatures and has good thermal insulation properties, making it suitable for hot and cold water supply.

- Long Lifespan: PPR pipes are resistant to corrosion, chemicals, and deposits, offering a long service life.

Disadvantages:

- Installation Costs: The installation process can be more labor-intensive due to heat fusion welding techniques required.

- UV Sensitivity: Like many plastics, PPR should not be exposed to UV light without protection.

Applications:

PPR pipes are primarily used in potable water supply systems, heating and cooling systems, and industrial applications due to their versatility and longevity.

Conclusion

When selecting piping material, it is essential to consider the specific requirements of your project, including temperature, pressure, chemical exposure, and cost-effectiveness. While PB has fallen out of favor due to its issues with durability, PE, PVC, PERT, and PPR remain viable options, each serving unique applications and offering distinct advantages. Making an informed decision based on a thorough understanding of these materials will contribute to the success of any plumbing project, ensuring efficiency and longevity in water transport systems. dcpipe-piping system expert