In the world of polymers, polyethylene stands out as one of the most widely used materials across various industries. Among its several types, High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE) are the most prominent. While they share a common basis in polyethylene, their properties, processing techniques, and applications differ significantly. This blog post aims to provide an in-depth analysis and comparison of these three forms of polyethylene, highlighting their unique characteristics and suitable applications.

What is Polyethylene?

Polyethylene is a thermoplastic polymer made from the polymerization of ethylene monomers. It is characterized by its lightweight, durable, and flexible nature, making it an ideal choice for a myriad of applications, from packaging to construction materials. There are several types of polyethylene, distinguished primarily by their density and branching in molecular structure. The primary types include HDPE, LDPE, and LLDPE.

High-Density Polyethylene (HDPE)

Characteristics:

- Density: HDPE has a density ranging from 0.941 to 0.965 g/cm³. Its high density is attributed to its tightly packed molecular structure, which results in a strong and rigid material.

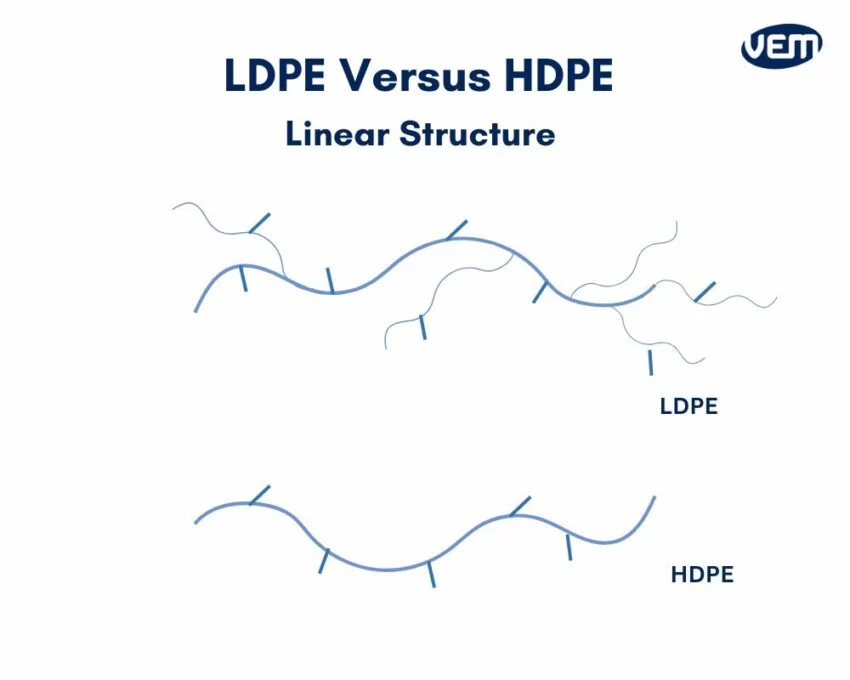

- Molecular Structure: The polymer chains in HDPE are largely linear, with minimal branching. This linear arrangement contributes to its strength and toughness.

- Thermal Resistance: HDPE exhibits a higher melting point (approximately 120-180°C) compared to its counterparts, making it suitable for applications requiring heat resistance.

Applications:

HDPE is favored in various industrial applications due to its strength and durability. Some common uses include:

- Packaging: HDPE is commonly used in manufacturing containers, bottles, and caps due to its excellent resistance to chemicals and moisture.

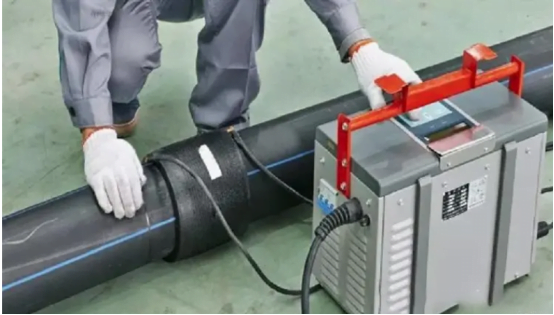

- Piping: Its high tensile strength makes HDPE suitable for producing piping systems for water and gas distribution.

- Geomembranes: HDPE is used in environmental applications for landfill liners and containment systems.

Advantages:

- High strength-to-density ratio

- Excellent chemical resistance

- Good impact resistance

- Recyclable, contributing to environmental sustainability

Low-Density Polyethylene (LDPE)

Characteristics:

- Density: LDPE has a density between 0.910 and 0.940 g/cm³, making it less dense than both HDPE and LLDPE.

- Molecular Structure: LDPE features a highly branched structure, which imparts flexibility and ductility but reduces its overall strength compared to HDPE.

- Thermal Resistance: LDPE has a lower melting point, typically around 105-115°C, which limits its use in high-temperature applications.

Applications:

LDPE is widely used for applications that require flexibility and low-density forms. Some notable uses include:

- Films and Bags: LDPE is commonly used to produce plastic bags, stretch films, and packaging materials. Its flexibility makes it ideal for these applications.

- Containers: Soft or squeezable bottles and containers often utilize LDPE due to its malleability.

- Insulation: LDPE is employed in the insulation of cables and wires due to its excellent electrical insulating properties.

Advantages:

- Flexible and lightweight

- Good resistance to moisture and chemicals

- Low-temperature flexibility

- Easily processed and molded

Linear Low-Density Polyethylene (LLDPE)

Characteristics:

- Density: LLDPE has a density range of approximately 0.915 to 0.935 g/cm³, placing it between HDPE and LDPE in terms of density.

- Molecular Structure: LLDPE consists of a linear chain with short branches, combining properties of both HDPE and LDPE. This structure provides a balance of strength and flexibility.

- Thermal Resistance: LLDPE’s melting point is also lower than HDPE but can vary significantly depending on the copolymerization used during production.

Applications:

LLDPE is highly versatile and is commonly employed in various fastening and packaging applications. Some specific uses include:

- Stretch Films: LLDPE is highly favored for producing stretch films due to its tensile strength and elastic properties.

- Blown Films: The flexibility and toughness of LLDPE make it ideal for manufacturing blown films used in retail packaging.

- Agricultural Films: Due to its UV resistance, LLDPE is commonly used in greenhouse coverings and mulch films.

Advantages:

- Excellent tensile strength and flexibility

- Good puncture resistance

- Versatile processing options

- Cost-effective for large-scale applications

Comparative Analysis

Mechanical Properties:

- Strength: HDPE exhibits superior tensile strength and is more rigid than both LDPE and LLDPE.

- Flexibility: LDPE offers maximum flexibility due to its highly branched structure, while LLDPE provides a balance of strength and flexibility.

Processing:

- Moldability: LDPE is easier to process and mold into intricate shapes due to its lower melting point and viscosity, whereas HDPE requires more advanced processing techniques due to its higher melting point.

- Production Techniques: LLDPE is produced using a different method (co-polymerization) that allows for enhanced strength and stretchability, offering distinct advantages in packaging applications.

Chemical Resistance:

- Resistance: HDPE has exceptional resistance to a wide range of chemicals, making it ideal for applications in harsh environments. LDPE also provides good chemical resistance but is generally not as robust as HDPE. LLDPE has mix resistance properties, which can vary depending on its formulation.

Conclusion

In conclusion, HDPE, LDPE, and LLDPE each serve distinct roles in the polyethylene family, offering unique characteristics that cater to various industrial and commercial needs. Understanding these differences is crucial for selecting the appropriate material for specific applications.

While HDPE is ideal for strength and durability, LDPE excels in flexibility and lightness, and LLDPE provides a favorable mix of both strength and elasticity. By analyzing these properties and their applications, manufacturers and consumers alike can make informed choices that lead to improved product performance and sustainability.

In the constantly evolving landscape of materials science, advancements in polymer technology will continue to shape the future applications of these versatile materials. dcpipe-piping system expert