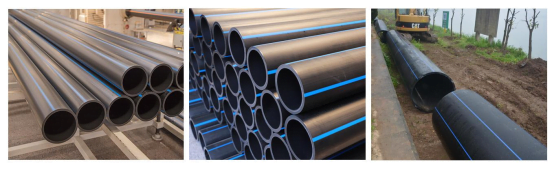

Overview: PE (Polyethylene) material is widely used due to its excellent performance. However, PE water supply pipes and PE gas pipes have distinct differences in terms of application and characteristics.

Different Uses and Applications

PE Water Supply Pipes: These are primarily used in urban water supply systems, providing clean drinking water to residents and industries.

PE Gas Pipes: Specifically designed for transporting natural gas and other gases, these pipes supply energy to both residential and industrial sectors.

Material Characteristics

PE Water Supply Pipes:

Made from PE80 or PE100 grade high-density polyethylene.

Produced using virgin materials with added masterbatch for increased oxidation resistance.

Focuses on corrosion resistance and hygiene, ensuring no contamination or odor in the water.

There are strict hygiene performance standards to guarantee the safety of the water and the longevity of the pipes.

PE Gas Pipes:

Emphasizes pressure resistance and sealing.

Uses a more uniform carbon black distribution and better aging resistance in the material mix.

Designed for a lifespan of 50 years, with a minimum service life of 30 years, and is subjected to a lifetime responsibility system.

Given the potential dangers of gas leaks, PE gas pipes have higher requirements compared to PE water supply pipes.

Installation and Usage Requirements

PE Water Supply Pipes:

Need to withstand certain water pressure and impact forces.

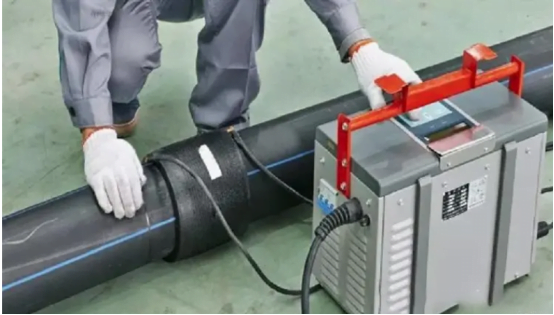

Typically installed using hot-melt or electrofusion connections to ensure sealing and reliability.

No strict diameter requirements, adjustments can be made based on site conditions.

PE Gas Pipes:

Must undergo rigorous testing and pressure checks before installation.

For pipes below DN63, electrofusion welding is mandatory.

For pipes between DN63 and DN110, electrofusion welding is recommended.

For pipes above DN110, there are no special welding requirements, but safety during use is a primary concern to prevent leaks.