Iron ore is one of the most important raw materials in the global economy, serving as the primary source of iron for steel production. The process of extracting iron ore involves a series of well-defined steps, from geological exploration to the eventual transportation of the mined product to various industries. This blog post aims to provide a comprehensive overview of the iron ore mining process, the global distribution of iron ore deposits, and an insight into some of the major mining companies involved in this critical industry. dcpipe pipeline expert

The Iron Ore Mining Process

The mining process for iron ore typically comprises several stages:

1. Exploration and Surveying

The first step in iron ore mining is exploration. Geologists conduct surveys and exploratory drilling to identify and evaluate potential iron ore deposits. Various geological techniques, including geophysical methods, geochemical assays, and classic field mapping, are employed. Once a viable deposit is located, drilling is used to collect samples, which are analyzed for iron content and other minerals.

2. Feasibility Studies

After identifying promising reserves, mining companies will conduct feasibility studies to determine the economic viability of extracting the ore. This includes analyses of the potential yield, market prices for iron ore, operational costs, and environmental impacts. Detailed financial modeling is undertaken to assess the return on investment and to secure necessary funding.

3. Mine Design and Planning

Once the feasibility study indicates a profitable venture, the next phase involves mine design and planning. This includes selecting the mining method: surface mining (open-pit mining) or underground mining. Open-pit mining is typically used when iron ore deposits are located relatively close to the surface, while underground mining becomes necessary when deeper deposits are present.

Mine planning encompasses environmental assessments and the development of a reclamation plan to restore the mined land post-extraction. Additionally, logistics planning for the transportation of the mined ore to processing plants is crucial at this stage.

4. Extraction

After planning, the extraction of iron ore begins. For open-pit mining, a series of steps are involved, such as stripping overburden, drilling, blasting, and hauling away the ore. The ores are usually blasted using explosives to break rock formations, followed by the use of heavy machinery like excavators and trucks to transport the ore to processing facilities.

5. Crushing and Grinding

Once the ore reaches the processing facility, it undergoes size reduction through crushing and grinding. This process reduces the ore into smaller particles, which enrich the iron content and prepare it for further processing. Magnetic separation and flotation are common methods employed for concentration after crushing, allowing the removal of impurities and enhancement of iron concentrations.

6. Pelletizing and Sintering

To improve the performance of iron ores in steelmaking, the concentrated ore is often converted into pellets or sinter. Pelletizing involves rolling the ore into balls and treating them at high temperatures, while sintering fuses small particles together into larger masses. This results in an intermediary product that is conducive for blast furnace operations.

7. Transportation

Finally, the processed iron ore is transported to steel manufacturing plants, which are often located near the coast to facilitate shipping. Transportation methods include railways, trucks, and ships, depending on the distance and geographical considerations.

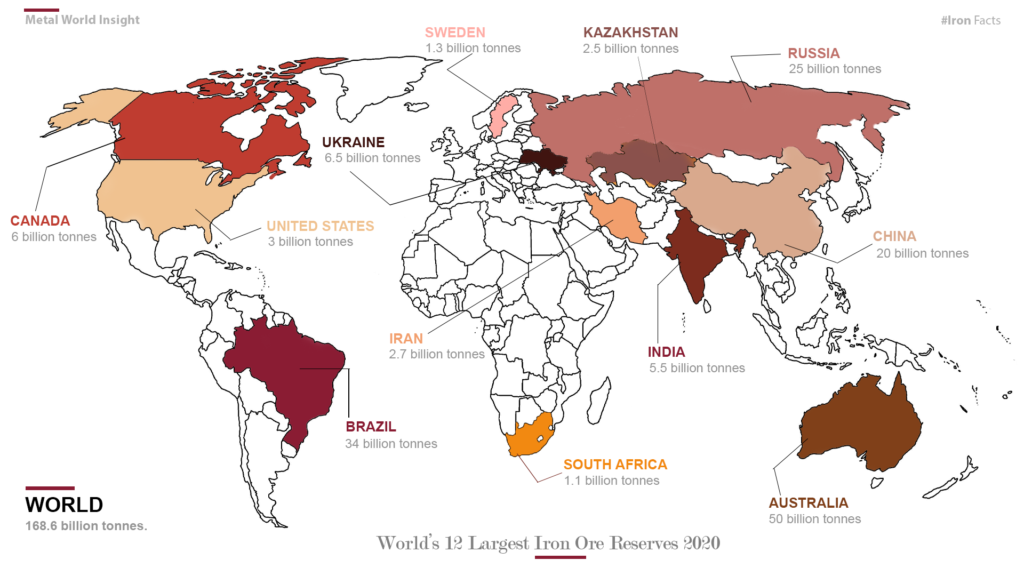

Global Distribution of Iron Ore

Iron ore deposits are found in many countries around the world, but a few regions stand out in terms of production and reserves:

1. Australia

Australia is the largest producer and exporter of iron ore, accounting for over 35% of global production. The Pilbara region in Western Australia is particularly rich in high-grade iron ore deposits, making it a cornerstone of Australia’s mining industry. Major companies operating in this region include BHP Billiton and Rio Tinto.

2. Brazil

Brazil follows Australia as a significant iron ore producer, with the Carajás Mine being one of the world’s largest iron ore mines. Brazil’s iron ore is known for its high quality, and Vale S.A. is the leading mining company in the country.

3. China

China, although primarily known for being the world’s largest consumer of iron ore, has significant deposits of its own. Iron ore mining in China is pivotal to its domestic steel production, with companies such as China Shenhua Energy Company and Ansteel Mining Corporation leading the charge.

4. India

India possesses a wealth of iron ore resources, particularly in the eastern states of Odisha and Jharkhand. The country’s iron ore is characterized by a mix of high and low-grade ores, and companies like National Mineral Development Corporation (NMDC) play a vital role in the industry.

5. Russia and Ukraine

Both Russia and Ukraine possess substantial iron ore reserves. In Russia, the Kola Peninsula holds significant deposits, while Ukraine is known for its Kryvyi Rih basin, a rich source of iron ore. Companies such as Metalloinvest in Russia and ArcelorMittal Kryvyi Rih in Ukraine are key players in these regions.

Major Iron Ore Mining Companies

1. BHP Billiton

BHP, an Australian multinational company, is one of the largest mining firms globally. Its iron ore assets are primarily located in Western Australia, where it operates the Newman, Jimblebar, and Mount Whaleback mines. BHP continually invests in technological advancements to enhance productivity and sustainability in its operations.

2. Rio Tinto

Also based in Australia, Rio Tinto is a major player in iron ore mining worldwide. The company’s Pilbara operations are known for their high-grade ore and efficient supply chains. Rio Tinto places a strong emphasis on sustainability, striving to reduce the environmental impact of its mining activities.

3. Vale S.A.

Vale, headquartered in Brazil, is the world’s largest producer of iron ore and nickel. Its operations are marked by the use of innovative technology to aid in extraction and environmental conservation. Vale’s Carajás Mine is notable for its high iron ore content, and the company has been advocating for sustainable mining practices.

4. Fortescue Metals Group

Fortescue is an emerging player in the iron ore sector, primarily based in Western Australia. The company has seen significant growth through strategic investments in infrastructure and technology, positioning itself as a low-cost producer in the iron ore market.

5. Anglo American

Anglo American has significant mining operations in Australia and Brazil, focusing not only on iron ore but also on a diverse range of minerals. The company emphasizes the importance of responsible mining practices, integrating sustainability into its business model.

Conclusion

Iron ore mining plays a crucial role in the global economy, driven by an ever-growing demand for steel in various industries. The mining process is multifaceted, encompassing exploration, extraction, processing, and transportation. With significant deposits located primarily in Australia, Brazil, China, and India, a few key players dominate the global market. As the iron ore industry evolves, innovations in technology and sustainability will shape its future, focusing on minimizing environmental impacts while meeting the demands of an increasingly industrialized world.

The iron ore sector remains a cornerstone of economic activity worldwide, and as we move toward a more sustainable future, its ability to adapt to changing demands will be closely watched by stakeholders across the globe. dcpipe pipeline expert