Modified polypropylene (MOPP) pipes have emerged as a revolutionary product in various industries due to their enhanced properties and performance compared to conventional materials. This blog post aims to provide a comprehensive exploration of modified polypropylene pipes, including their manufacturing processes, advantages, applications, and future trends in the market.

What is Modified Polypropylene?

Modified polypropylene is a thermoplastic polymer derived from polypropylene, which is further enhanced through various additives, fillers, and copolymers. These modifications are designed to improve the inherent properties of polypropylene, such as impact resistance, stiffness, heat resistance, and overall durability. The modification process typically involves altering the chemical structure of the polymer or incorporating other materials, resulting in a product that better meets the diverse requirements of modern applications.

Manufacturing Process of Modified Polypropylene Pipes

The production of modified polypropylene pipes involves several critical steps, each essential for achieving optimal quality and performance.

1. Polymerization

The manufacturing process begins with the polymerization of propylene monomers in the presence of catalysts. This step forms the base polypropylene resin, which serves as the foundation for further modifications.

2. Modification

Following polymerization, the polypropylene undergoes modification using various additives to enhance its properties. Common modifications include:

- Additives: Incorporating materials such as elastomers, impact modifiers, or flame retardants can significantly enhance impact resistance, flexibility, and fire safety.

- Copolymerization: Blending polypropylene with other polymers through copolymerization can produce materials with specific attributes, such as improved transparency or resistance to certain chemicals.

- Reinforcement: Adding fibrous materials like glass fibers or mineral fillers can enhance the mechanical strength and stiffness of the pipes.

These modification techniques allow manufacturers to tailor the end product to specific performance criteria, resulting in a diverse range of modified polypropylene pipes suitable for various applications.

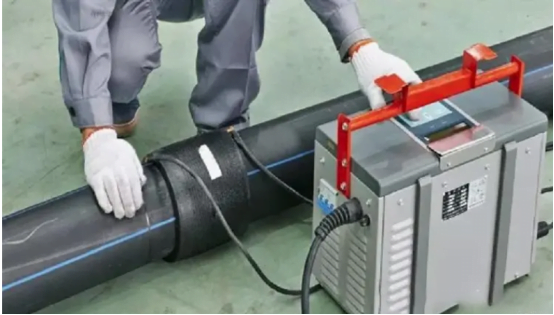

3. Extrusion

The modified polypropylene resin is then fed into an extruder, where it is melted and formed into pipes through a continuous extrusion process. This step allows for the consistent production of pipes with uniform thickness and dimension.

4. Cooling and Finishing

Once extruded, the pipes are rapidly cooled to solidify the material. The pipes may undergo additional finishing processes, such as cutting, surface treatment, or printing, to meet customer specifications and ensure quality control.

Advantages of Modified Polypropylene Pipes

Modified polypropylene pipes boast several advantages that make them an attractive option for both manufacturers and end-users, including:

1. Enhanced Mechanical Properties

The modifications to the standard polypropylene resin provide MOPP pipes with superior mechanical strength, allowing them to withstand high-pressure applications and resist deformation over time. This durability contributes to a longer service life, reducing the need for frequent replacements.

2. Chemical Resistance

Modified polypropylene exhibits excellent resistance to a wide variety of chemicals, making it suitable for transporting corrosive substances. This property is beneficial in industries such as chemical processing and wastewater management.

3. Lightweight

MOPP pipes are considerably lighter than traditional materials like metal or concrete, making them easier to install and handle. This lightweight characteristic can result in reduced transportation costs and simpler installation processes.

4. Thermal Stability

The modifications made to polypropylene can enhance its thermal stability, allowing MOPP pipes to maintain performance under varying temperature conditions. This is particularly valuable in applications where temperature fluctuations are common.

5. Environmental Considerations

Modified polypropylene is often recyclable, contributing to more sustainable practices in construction and manufacturing. The ability to repurpose material reduces landfill waste and supports the circular economy.

Applications of Modified Polypropylene Pipes

The versatility of modified polypropylene pipes allows for their application across various sectors, including:

1. Plumbing and Drainage Systems

MOPP pipes are widely used in plumbing and drainage systems due to their excellent resistance to moisture and chemical corrosion. They can be utilized for both residential and commercial applications, ensuring safe and efficient water transport.

2. Industrial Applications

In industrial settings, MOPP pipes are used to transport chemicals, fluids, and gases. Their resistance to aggressive substances makes them a reliable choice for chemical processing, oil and gas industries, and waste management systems.

3. HVAC Systems

Modified polypropylene pipes are gaining traction in heating, ventilation, and air conditioning applications due to their lightweight nature and thermal stability. They can efficiently handle hot or cold air and are often used in ductwork.

4. Agriculture

In the agricultural sector, MOPP pipes are employed for irrigation systems, enabling efficient water distribution while resisting degradation from environmental factors.

Future Trends in the Market

The market for modified polypropylene pipes is poised for growth due to several trends, including:

1. Technological Advancements

Ongoing research and development in polymer science continue to lead to the creation of even more sophisticated formulations of modified polypropylene, enhancing performance characteristics and expanding application possibilities.

2. Increasing Demand for Sustainable Solutions

As industries seek to adopt more sustainable practices, the demand for recyclable and environmentally friendly materials like modified polypropylene is expected to rise. Manufacturers are likely to focus on producing pipes that minimize environmental impact.

3. Expanding Infrastructure Projects

With global investments in infrastructure development, the demand for durable and efficient piping solutions is anticipated to increase. Modified polypropylene pipes, with their superior mechanical and chemical properties, are well-positioned to meet these demands.

Conclusion

Modified polypropylene pipes represent a significant advancement in the field of materials science, offering a unique blend of durability, chemical resistance, and versatility. Their growing adoption across various industries underscores their value as a reliable solution for modern piping needs. As technology continues to evolve and sustainability becomes increasingly important, we can expect to see further innovations and applications for modified polypropylene pipes in the near future.

In summary, understanding the comprehensive benefits and applications of modified polypropylene pipes will help professionals and decision-makers make informed choices for their projects, ensuring maximum performance and reliability in their piping systems. dcpipe-piping system expert