In water supply and drainage systems, both PE pipes and PE steel wire mesh skeleton composite water supply pipes are commonly used materials. However, they differ in structure, performance, and application. Below is a detailed analysis of these differences, summarized by Dingchang Xinlong based on years of practical experience.

Material and Structural Differences

PE Pipes:

Made from a single polyethylene (PE) material.

Offers excellent flexibility, corrosion resistance, and durability.

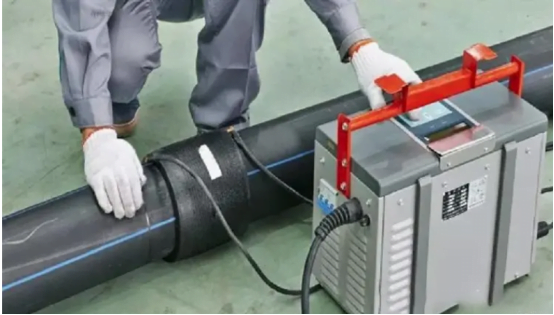

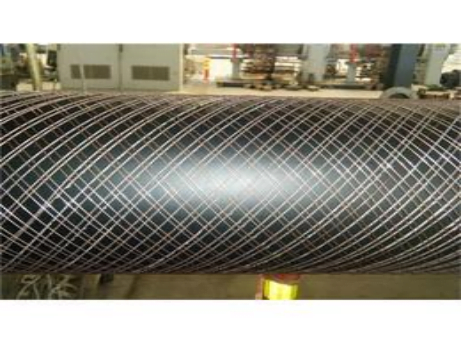

PE Steel Wire Mesh Skeleton Composite Water Supply Pipes:

Built on the foundation of PE pipes but reinforced with a high-strength steel wire mesh skeleton inside.

This design enhances the pipe’s pressure-bearing capacity and impact resistance while retaining the excellent properties of PE pipes.

Performance Characteristics

PE Pipes:

Known for their outstanding corrosion resistance, wear resistance, and flexibility.

Suitable for a wide range of environments and conditions in water supply and drainage systems.

PE Steel Wire Mesh Skeleton Composite Water Supply Pipes:

In addition to the benefits of PE pipes, these pipes offer significantly higher pressure resistance and stability.

Ideal for environments where pipes need to withstand greater pressure and impact.

Application Fields

PE Pipes:

Due to their excellent performance and lower cost, they are widely used in urban water supply and drainage, agricultural irrigation, and industrial fluid transportation.

PE Steel Wire Mesh Skeleton Composite Water Supply Pipes:

More commonly used in scenarios that require higher pipe performance, such as high-rise building water supply, fire protection systems, and petrochemical industries.