Longwall mining is a highly efficient and productive method of underground coal mining that has gained prominence in the industry due to its ability to extract large quantities of coal from deep seams while minimizing surface disruption. This blog post aims to provide a comprehensive overview of longwall mining, covering its techniques, benefits, challenges, and its future in the context of sustainable mining practices. dcpipe pipeline expert

What is Longwall Mining?

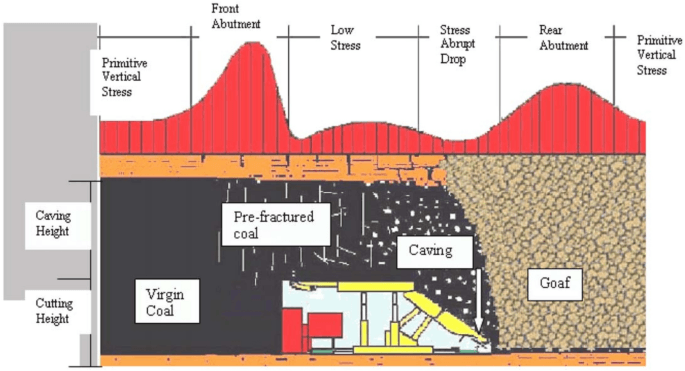

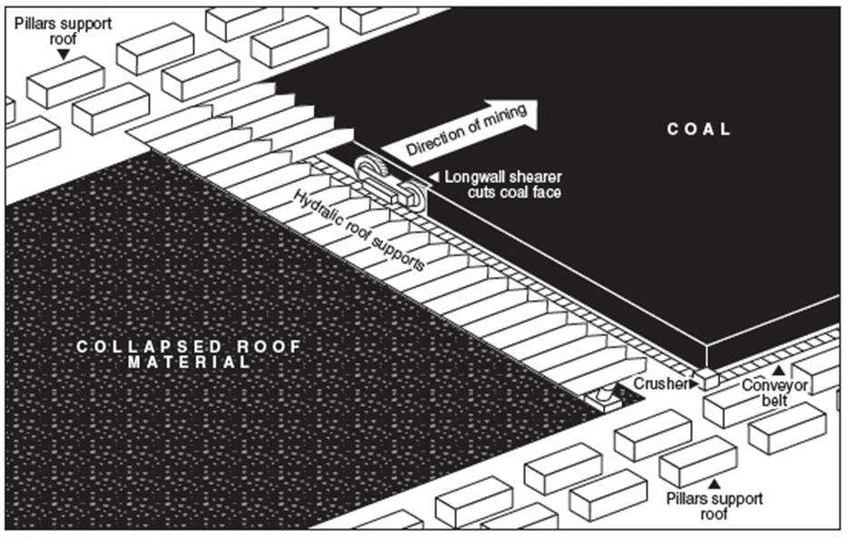

Longwall mining involves the extraction of coal in a continuous process using a longwall face, which is typically 250 to 400 meters long. The longwall miner moves horizontally across the coal seam, systematically removing coal with a specialized machine known as a shearer. As the coal is harvested, the mined area is reinforced using hydraulic supports to control ground pressure and prevent collapses, leaving behind a stable and safe work environment.

Techniques of Longwall Mining

- Site Preparation: Longwall mining begins with extensive planning and preparation. Detailed geological surveys and assessments are conducted to identify viable coal seams. Preparation also includes the development of access roads and transportation systems for moving coal from the mine to the surface.

- Development of Gate Roads: The first step in longwall mining is the establishment of gate roads. These are pathways leading to the longwall face. Gate roads are developed using conventional mining methods, which involves creating entries parallel to the coal seam. Once the gate roads are prepared, the longwall system can be installed.

- Installation of Longwall Equipment: The longwall setup includes the shearer, armored face conveyor (AFC), and hydraulic supports. The shearer is responsible for cutting the coal, while the AFC transports the extracted coal to the surface. Hydraulic supports serve as shields to maintain stability above the mined area, allowing for the controlled collapse of the overburden after the coal is removed.

- Coal Extraction Process: The coal extraction process can take place in two main phases: mining and retreating. In the mining phase, the shearer moves along the longwall face, cutting coal down to the conveyor. Once the coal is extracted, the mine operators initiate the retreating phase, pulling back the hydraulic supports as the mined area collapses safely, effectively recycling the space for coal extraction.

- Monitoring and Control: Longwall mining involves sophisticated monitoring technologies. Real-time data on geological conditions, structural integrity, and the performance of machinery are crucial for ensuring operational safety and efficiency. Technologies such as ground-penetrating radar (GPR), seismic monitoring systems, and automated machinery have become increasingly essential in modern longwall operations.

Benefits of Longwall Mining

- High Production Rates: One of the most notable advantages of longwall mining is its ability to achieve high production rates. When well-managed, longwall operations can yield several thousand tons of coal per hour, making it a preferred method for large-scale coal extraction.

- Efficiency and Safety: Longwall mining is generally safer than traditional room-and-pillar mining, as the hydraulic supports protect workers from roof falls. The continuous nature of the operation also reduces the number of workers required in hazardous mining environments.

- Minimized Surface Impact: Due to the small footprint of the surface facilities compared to other mining methods, longwall mining creates less surface disruption. The subsidence that occurs post-extraction can often be managed and mitigated through effective planning.

- Resource Recovery: Longwall mining allows for a higher recovery rate of coal from the seam compared to conventional methods. It is estimated that longwall mining can recover up to 80% of the available coal in a given seam, translating into more efficient resource utilization.

Challenges of Longwall Mining

- Initial Capital Investment: The upfront costs associated with setting up a longwall mine can be substantial. Investments in specialized equipment, infrastructure, and technology are significant and can deter some operators from adopting this method.

- Geological and Technical Constraints: Longwall mining is heavily dependent on geological conditions. Variations in seam thickness, rock strength, and the presence of faults can complicate mining operations. When geological factors are unfavorable, the mining process can be inefficient or hazardous.

- Environmental Impact: While longwall mining is known for its reduced surface disturbance, it can cause subsidence, which may negatively impact surrounding ecosystems, water sources, and infrastructure. Understanding and managing these environmental impacts are critical for maintaining a social license to operate.

- Labor Challenges: The introduction of automation and advanced technology in longwall mining may potentially displace certain job categories within the industry. Balancing technology with workforce needs is essential for the future sustainability of longwall mining operations.

The Future of Longwall Mining

As demands for coal continue to evolve in the context of global energy needs, longwall mining will need to adapt. Emphasis on sustainable mining practices, carbon management, and minimized environmental impact is growing. The industry is also moving towards integrating more automation and digital technologies, enhancing the efficiency and safety of operations.

Moving forward, longwall mining must focus on improving resource recovery while ensuring that economic, social, and environmental factors are balanced effectively. Innovations in carbon capture and storage, along with ongoing research into alternative energy sources, may also influence the future direction of longwall mining as the world seeks a more sustainable energy paradigm.

Conclusion

Longwall mining stands as a testament to the advancements made in mining technologies and practices. With its ability to produce high volumes of coal efficiently and safely, it plays a vital role in the energy landscape. However, the challenges it faces, particularly in the evolving regulatory and ecological environment, necessitate a cautious yet proactive approach to mining operations. As the sector transforms, embracing innovation and sustainability will be paramount to ensuring the long-term viability of longwall mining in the years to come. dcpipe pipeline expert